Dry electrode technology is a battery electrode manufacturing process without solvents, and both anode and cathode electrode preparation can be applied. The dry electrode process eliminates the solvent and also enhances the performance of the battery electrode, and simplifies the electrode preparation process with less equipment investment.

Compared to wet electrode manufacturing, the process innovation of dry electrode manufacturing has 4 major advantages.

1) Simplification of battery electrode manufacturing process

The core of dry electrode technology lies in the abandonment of "wet", without the use of solvents, simplifying the wet process of battery electrode slurry making, coating, drying and solvent recovery.

2) Improve the energy density of battery cells

The electrodes prepared by dry electrode technology can have higher compaction density and hold more active material.

Moreover, discarding the solvent results in better integration of the cathode material, facilitating lithium cathode replenishment and reducing the capacity loss during the first cycle.

3) Adapting to the direction of battery material systems

Currently, EV battery material systems are gradually moving toward high nickel-doped silicon.

Dry electrode technology can both attenuate the effect of humidity on the performance of high nickel anode electrodes and provide greater tolerance to the expansion of silicon-based cathode electrodes.

4) Extend the battery cell life

The battery life has been significantly improved by not using binder.

The vision of dry electrode preparation is good, smaller production plant, smaller equipment footprint, less energy consumption, lower battery cell cost, but the commercial implementation of the abandonment of "wet" is not easy.

However, there is still a gap between the dry electrode preparation process and the wet electrode preparation in terms of industrialization. The technical difficulty of dry electrode preparation lies in the thickness control of formed film and material uniformity.

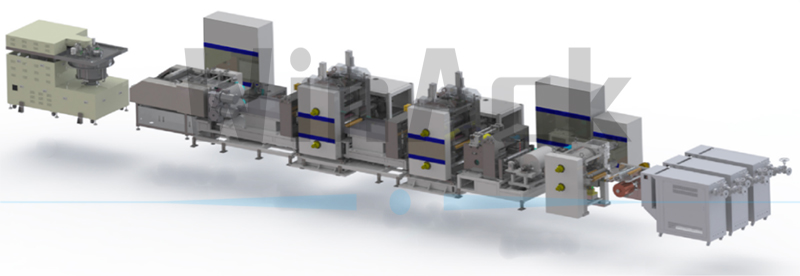

Figure 1. Dry Electrode Manufacturing Equipment

For this, WinAck's solution for dry electrode manufacturing is a double steel belt roll forming system and a multi-stage roll press system.

1) Dry electrode film forming process equipment - Double steel belt roll forming system

The manufacturing of dry electrode self-supporting film is realized by double steel belt roll pressing technology. The steel belt system can be used as a carrier for self-supporting electrode film, which reduces the breakage of electrode film during the process of roll-to-roll manufacturing and high-speed movement.

2) Dry electrode film forming and thinning process equipment - Multi-stage roller press system

The electrode materials powder is rolled into a thick film by roll pressing technology, and then wound up or laminated with the current collector after multi-stage hot pressing and thinning to ensure that the film is thinned to the specified thickness and increase the compaction density without breaking the tape.

WinAck Group can provide complete battery electrode manufacturing solutions. Come by, contact us for a solution that can help you succeed. For better batteries, Win & Ack!