Lithium-ion battery winding machine has been widely used in the battery electrode manufacturing process and is a necessary production equipment for the electrode winding process.

Model:

WA-EW-SA270SElectrodes width:

33~68mm (Customizable)Electrodes length:

100~2000mm (Customizable)Separator width:

35~70mm (Customizable)Strapping tape width:

8~50mm (Customizable)Winding needle diameter:

φ2.0mm~φ5.0mm (Optional and customizable)Product Detail

Battery Electrode Winding Process

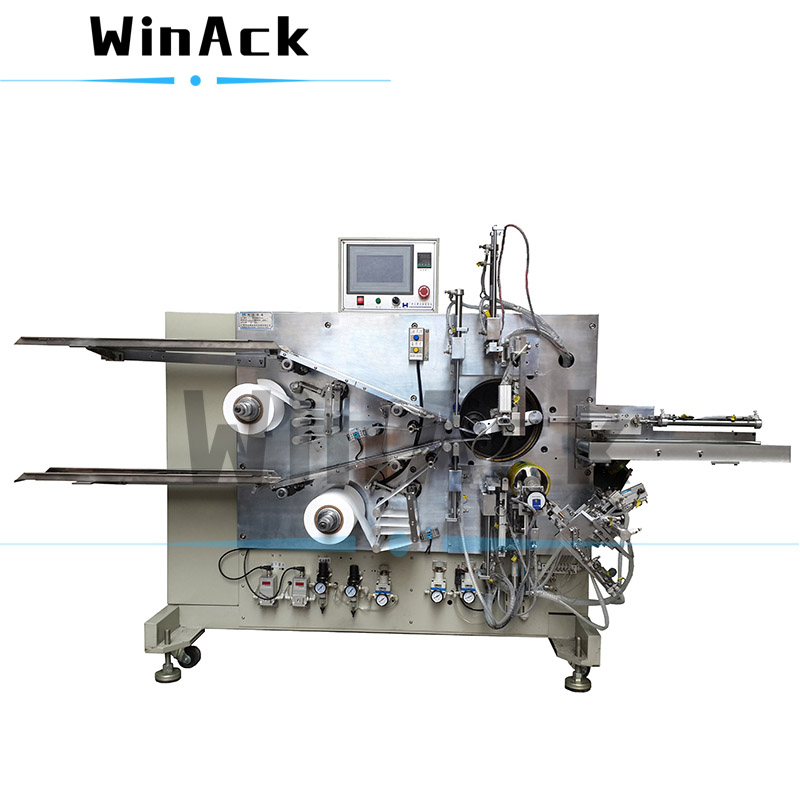

Lithium-ion Battery Winding Machine

Product overview:

Lithium-ion battery winding machine is the necessary production equipment for battery electrode winding process. In the battery electrode winding process, single pieces of battery electrode are manually loaded, and the battery cell winder automatically unwinds the rolled separator for winding. After the battery electrode winding is completed, the strapping tape is automatically applied, automatically cut off, and automatically unloaded the finished wound cells.

Scope of application:

This battery cell winder can semi-automatically complete the battery electrode winding process of single electrodes and rolled separator.

Applicable incoming material specifications

|

Incoming materials |

Length (mm) |

Width (mm) |

Thickness (μm) |

Max. outer diameter (mm) |

Inner diameter (mm) |

||

|

Range |

Range |

Deviation |

Range |

Deviation |

|||

|

Anode electrodes |

100~2000 |

33~68 |

0.2 |

60~200 |

5 |

- |

- |

|

Cathode electrodes |

100~2000 |

33~68 |

0.2 |

60~200 |

5 |

250 |

76 |

|

Battery separator |

Rolled |

35~70 |

0.2 |

16~25 |

- |

150 |

76 |

|

Battery strapping tape |

Settable |

8~50 |

0.2 |

- |

- |

- |

- |

Kindly reminder: The above specifications are for reference only and can be adjusted according to actual requirements.

Features:

1)The rolled battery separator can be continuously unwound and the tension of the battery separator can be adjusted in the range: 0.2nm~5nm and kept constant.

2) The tension of the electrodes can be controlled during the electrode winding process. PLC and precision encoder for constant tension control, supplemented by pressure sensors, ensure uniform tension throughout the battery electrode winding process.

3)The width of the electrode guide plate can be adjusted to match different widths of electrodes with high dimensional accuracy and wear resistance and smoothness.

4) This lithium-ion battery winding machine adopts horizontal gluing, with large adjustment of gluing length and width, which guarantees the appearance and dimensional quality of the winded cells.

5) The battery winding machine can be equipped with a range of winding needle diameters from 2.0mm to 5.0mm, providing a wide range of applications and flexibility.

6) The lithium battery winding machine is equipped with a high-strength material winding needle, which can be pulled out smoothly without affecting the neatness of the already wound cells, and without scratching the battery separator or causing the wound cells to form a spiral.

7) The yield rate of the battery electrode winding process can reach 98%, and the deviation of the center distance of the battery tabs is ≤ ±0.5mm.

Technical Specifications

|

Product name |

Lithium-ion Battery Winding Machine |

|

Product model |

WA-EW-SA270S |

|

Production speed |

8~13PCS/min |

|

Utilization rate |

≥98% |

|

Yield rate |

≥98% |

|

Width of electrodes |

33~68mm (Customizable) |

|

Length of electrodes |

100~2000mm (Customizable) |

|

Width of battery separator |

35~70mm (Customizable) |

|

Winding needle diameter |

φ2.0mm~φ5.0mm (Optional and customizable) |

|

Width of battery strapping tape |

8~50mm (Customizable) |

|

Winding alignment |

≤0.3mm |

|

Alignment of electrode and separator |

≤±0.5mm |

|

Alignment of anode electrode and cathode electrode |

≤±0.5mm |

|

Position deviation of battery tabs |

≤±0.5mm |

|

Control method |

Touch Panel & PLC |

|

AC input power |

Single-phase 220VAC±10% / 50Hz (Customizable) |

|

Power: 1500W |

|

|

Input compressed air supply |

0.4~0.6MPa |

|

Size(L*W*H) |

1200*1200*1550mm |

|

Weight |

About 800kg |