This professional battery tab spot welder is for battery cell production, suitable for welding tabs-to-terminals connections, including copper tabs, nickel tabs and stainless-steel tabs.

Model:

WA-SW-M80ZTSpot welder type:

Manual typeWelding head:

Pneumatic driveApplication:

Battery cell tabs-to-terminals connectionsWarranty:

One year warranty with lifetime supportNote 1:

Workpiece material: Nickel, Stainless steel, CopperNote 2:

Thickness of the tabs: 0.05~0.80mm (Customizable)Product Detail

Product overview:

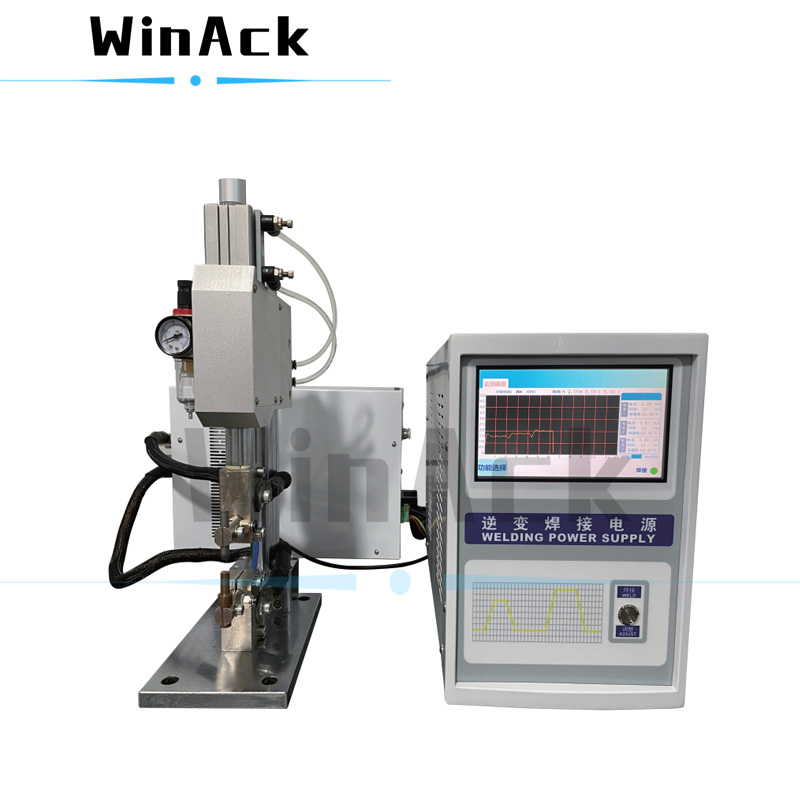

The battery tab spot welder is a professional manual type battery tab welding machine, which is used for the welding of battery cell tabs-to-terminals connections, and the welding is stable and reliable. It is mainly composed of an inverter DC power supply and a head-to-head welding head.

Based on the resistance between the contact surfaces of the two workpieces, the battery tab spot welder instantly passes a low voltage and a large current, so that the two metal contact surfaces that are butted are instantly heated and melted, thereby completing the welding.

Scope of application:

This battery tab spot welder is suitable for welding pure nickel tabs, stainless steel tabs and copper tabs with a thickness of 0.05~0.80mm.

In addition to battery tabs, it is also suitable for welding other workpieces made of pure nickel, stainless steel and copper.

Features:

1) This battery cell welder is equipped with a head-to-head welding head, which realizes the welding of copper tabs and copper terminal connections.

2) Head-to-head welding is designed to ensure strong, stable and reliable welding of high thickness materials. It can weld pure nickel, stainless steel and copper with a thickness of 0.05~0.80mm.

3) In addition to the welding of tabs-to-terminals connections of battery cells, other workpieces such as strips, wires, etc. can also be welded.

4) The output of the battery cell welder is low voltage and high current, which can be used for firm welding under the premise of ensuring the safety of the operator.

Technical specifications

|

Product name |

Battery Tab Spot Welder |

|

Product model |

WA-SW-M80ZT |

|

Product type |

Manual type |

|

Input power |

AC380V±10%, 50/60Hz |

|

Input compressed air source |

0.4~0.8MPa |

|

Welding speed |

0.5~0.8s/Single-welding |

|

Main control unit of the controller |

DSP chip |

|

Number of welding pulses |

3 |

|

Inverting frequency |

4KHz |

|

Maximum short-circuit output current |

8000A |

|

Maximum output power of transformer |

15KVA |

|

Control mode |

1) Constant current control 2) Constant voltage control |

|

Adjustable range of welding time |

1.0ms~20.0ms Accuracy: 0.1ms |

|

Cooling mode |

Forced air cooling |

|

Welding needles |

3mm (Customizable) |

|

Battery tabs details |

Material: Pure Nickel, Stainless Steel and Copper Strips |

|

Thickness: 0.05~0.80mm |