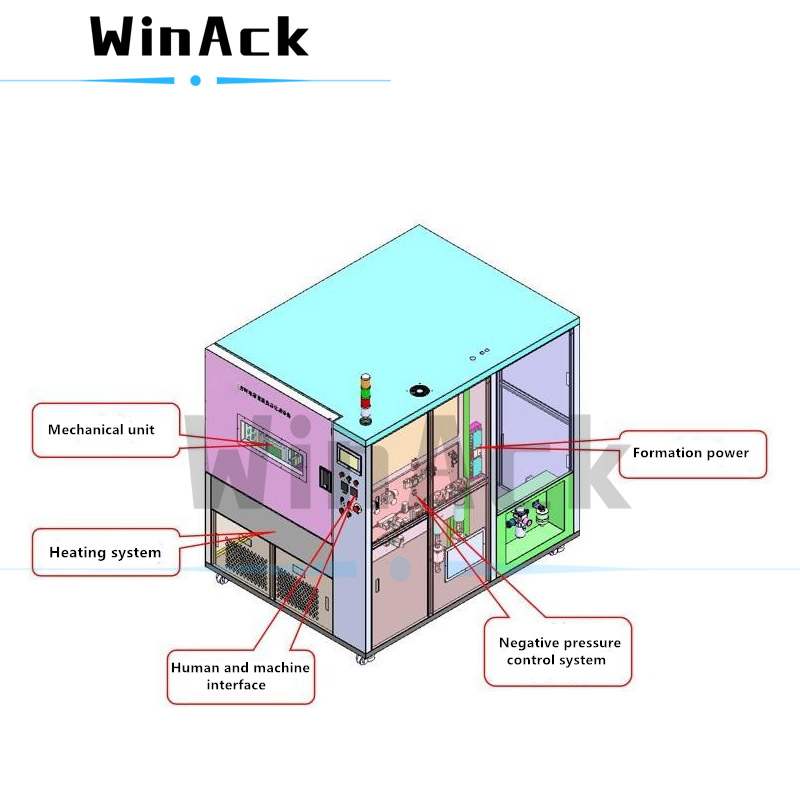

The prismatic cell battery formation machine is a professional battery SEI formation system, equipped with high temperature and negative pressure system, as well as formation power and control software.

Model:

WA-BFM-P5V60A-N-HTest channels:

16CH/SET (Customizable)Voltage range/CH:

25 mV ~5000mV (Customizable)Voltage accuracy:

±(0.05%FS+0.05%RD)Current range/CH:

300mA~60000mA (Customizable)Current accuracy:

±(0.05%FS+0.05%RD)Note 1:

Temperature range: RT+15℃~60℃(Customizable)Note 2:

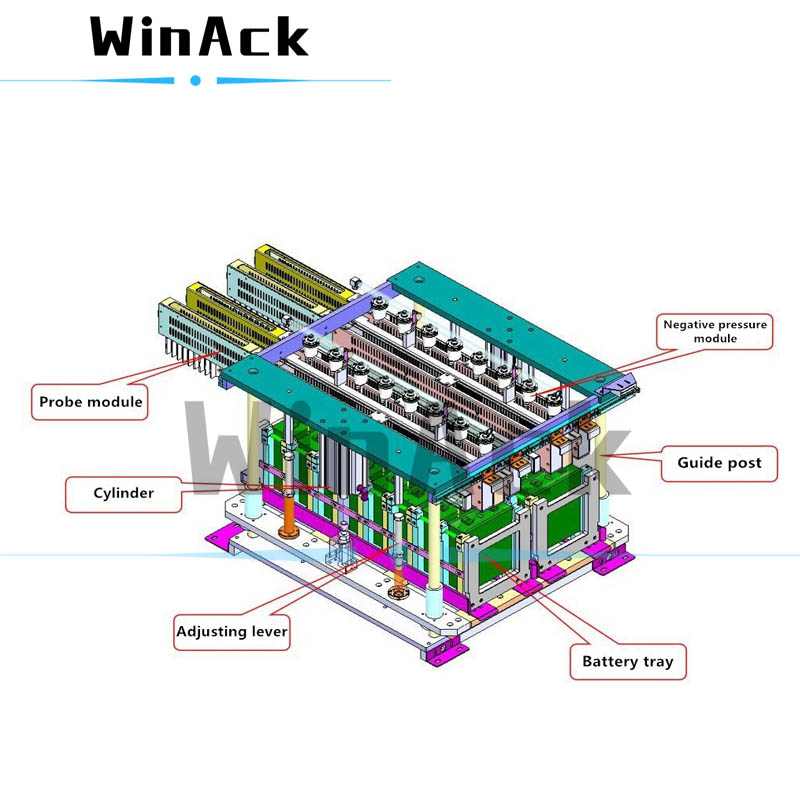

Negative pressure nozzle & Battery restraint trayProduct Detail

Prismatic Cell Formation Machine with High Temperature and Negative Pressure System

Product overview:

The prismatic cell battery formation machine is mainly composed of a high temperature and negative pressure formation cabinet, a 16CH-5V60A formation power module, a negative pressure control system, two battery restraint trays, an industrial PC and a professional formation control software.

|

Lithium-ion Battery SEI Formation Machine (Both voltage and current can be customized) |

||

|

Product model |

Voltage range / CH |

Current range / CH |

|

WA-BFM-5V3A |

0V~5V |

15mA~3A |

|

WA-BFM-5V6A |

0V~5V |

30mA~6A |

|

WA-BFM-5V10A |

0V~5V |

50mA~10A |

|

WA-BFM-5V20A |

0V~5V |

100mA~20A |

|

WA-BFM-5V30A |

0V~5V |

150mA~30A |

|

WA-BFM-5V60A |

0V~5V |

300mA~60A |

|

For more product models, please click "Battery Formation and Grading System" to view or contact us. |

||

Scope of application:

The prismatic cell battery formation machine is mainly used for the high temperature and negative pressure formation process of prismatic cells. The main function is to cooperate with the energy feedback power module to provide the current, voltage, capacity, temperature, negative pressure and step control required for lithium ion battery SEI formation. So as to realize the process monitoring and protection of the battery formation, and collect the data during the battery formation process.

Features:

1) Powerful formation power and control software

The prismatic cell battery formation machine adopts the energy feedback technology, which can save electricity costs and is environmentally friendly.

The battery SEI formation system supports different channels of lithium-ion battery cells are set with different formation processes, which is convenient for comparing the advantages and disadvantages of different formation processes. In addition, it supports a variety of formation steps, and the control precision is high.

2) High temperature and negative pressure formation process

The prismatic cell battery formation machine is equipped with a high temperature and negative pressure system to support the high temperature and negative pressure formation process of lithium-ion battery cells.

3) Strong compatibility

The battery SEI formation system has a modular design for easy adjustment and maintenance, and is compatible with a wide range of prismatic battery sizes.

Technical specifications

|

Product name |

Battery Formation Machine |

|

|

Product model |

WA-BFM-P5V60A-N-H |

|

|

Channel |

16CH |

|

|

Battery cell type |

Prismatic cell |

|

|

Power supply |

AC380V ±15% / 50Hz Three-phase five-wire system |

|

|

Rated Power: 10KW |

||

|

Compressed air source |

Pressure: 0.5~0.7MPa |

|

|

Flow: 1m3/h |

||

|

Vacuum source |

Vacuum: -100~0KPa |

|

|

Flow: 0.5m3/h |

||

|

Formation power module (16CH - 5V60A) |

Charging current range |

300~60000mA |

|

Discharge current range |

300~60000mA |

|

|

Current accuracy |

±(0.05%FS+0.05%RD) |

|

|

Charging voltage range |

25~5000mV |

|

|

Discharge voltage range |

25 ~5000mV |

|

|

Voltage accuracy |

±(0.05%FS+0.05%RD) |

|

|

High temperature and negative pressure formation cabinet |

Temperature range |

RT+15℃~60℃ |

|

Temperature uniformity |

±3℃ |

|

|

Probe pressing times |

≥30,000 times |

|

|

Nozzle life |

≥500 times or 3 months |

|

|

Battery cell temperature sensor |

1PCS/CH |

|

|

Temperature sensor collection accuracy |

±1℃ |

|

|

Battery restraint tray |

QTY |

2 SETS |

|

Channels |

8CH/SET |

|

|

Temperature resistance |

80℃ |

|

|

Flame retardant grade |

V-0 |

|

|

Host computer |

1 SET |

|

|

Formation monitoring and control software |

1 SET |

|

|

Operating temperature |

0~40℃ |

|

|

Operating humidity |

0.1%~85% |

|

|

Site load-bearing requirements |

≥550kg/m2 |

|

|

Noise |

<75dB |

|

|

Dimensions(W*D*H) |

About 1250*1250*2100mm |

|

|

Weight |

About 1000KG |

|