The Direction of Improvement of Electrolyte Filling Machines

Feb 20 , 2023

The Direction of Improvement of Electrolyte Filling Machines

Feb 20 , 2023

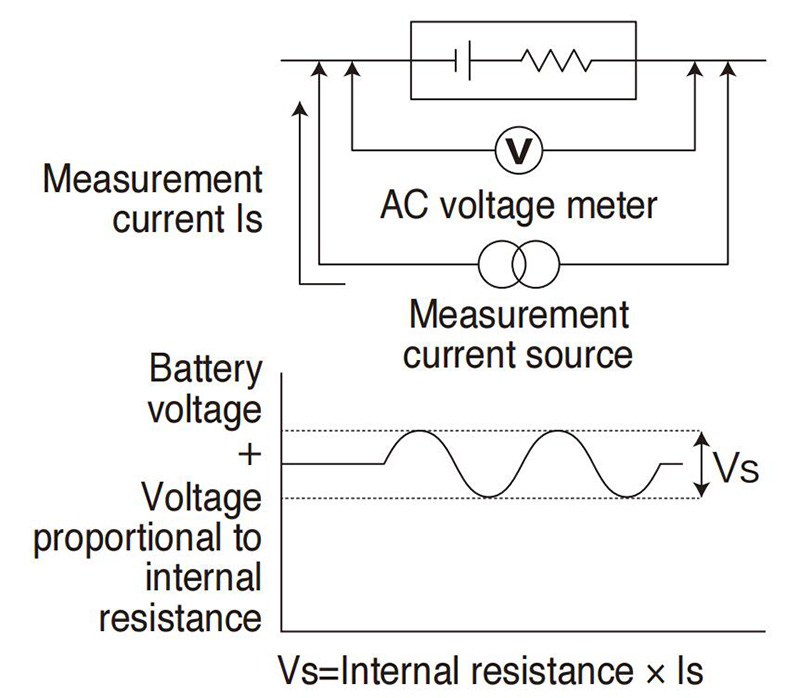

Battery Internal Resistance Test: ACIR and DCIR | Battery Testing

Feb 06 , 2023

Battery Internal Resistance Test: ACIR and DCIR | Battery Testing

Feb 06 , 2023

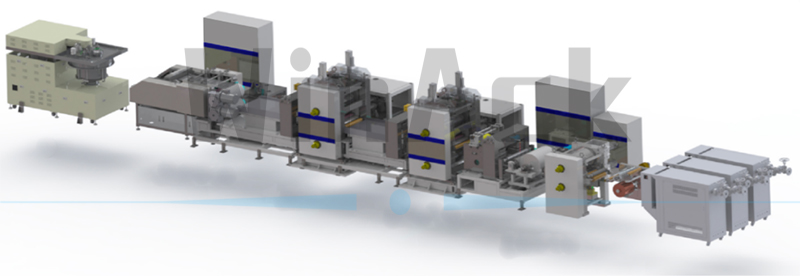

Dry Electrode Manufacturing Process and Equipment

Dec 05 , 2022

Dry Electrode Manufacturing Process and Equipment

Dec 05 , 2022

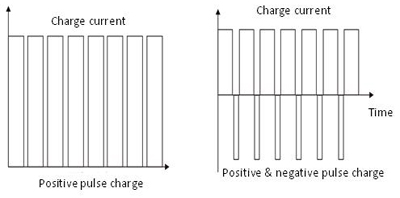

EV Battery Energy Efficiency Testing | EV Battery Testing

Nov 21 , 2022

EV Battery Energy Efficiency Testing | EV Battery Testing

Nov 21 , 2022

EV Battery Power and Internal Resistance Testing | EV Battery Testing

Nov 08 , 2022

EV Battery Power and Internal Resistance Testing | EV Battery Testing

Nov 08 , 2022

EV Battery Capacity and Energy Testing | EV Battery Testing

Nov 01 , 2022

EV Battery Capacity and Energy Testing | EV Battery Testing

Nov 01 , 2022

System Function Testing of EV Batteries | EV Battery Testing

Oct 27 , 2022

System Function Testing of EV Batteries | EV Battery Testing

Oct 27 , 2022

Lithium-ion Battery Safety Testing | WinAck Group

Oct 21 , 2022

Lithium-ion Battery Safety Testing | WinAck Group

Oct 21 , 2022