In the past two years, FinDreams Battery (BYD), SVOLT Energy, EVE, CALB, Sunwoda and other battery cell manufacturers are using electrode stacking process for prismatic cell products on a large scale, "electrode stacking process & long thin size blade cells" has become the mainstream of the trend of prismatic cells.

In fact, with the popularity of electric vehicles, battery cells are being designed in larger and larger sizes to meet endurance, safety, lifespan and cost requirements. In this case, the shortcomings of the electrode winding process are magnified, such as the inevitable large bending deformation of the coating material on the electrode, which leads to the formation of dropped material and dead zones at the bend. Also, during the electrode winding process, the tension on the electrode sheet and the battery separator is easily uneven, resulting in wrinkles and poor alignment.

Compared with the electrode winding process, the electrode stacking process is more suitable for large prismatic cells, and the advantages are beginning to emerge. For more details, please click “Features of Lamination & Stacking Process for Lithium-ion Battery Cells” to browse.

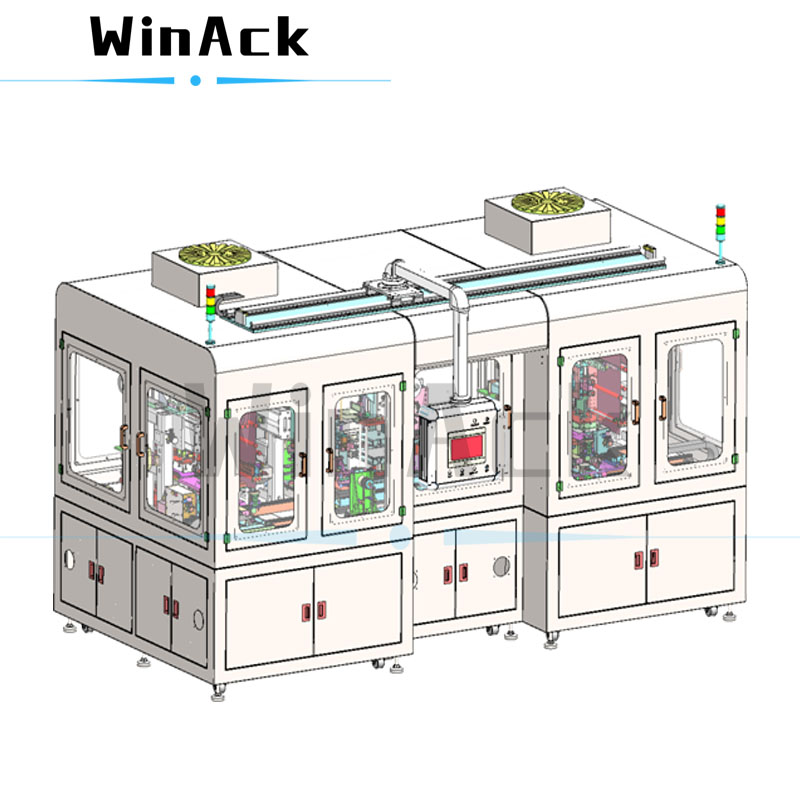

Picture 1. Duplex-station Battery Cell Stacking Machine

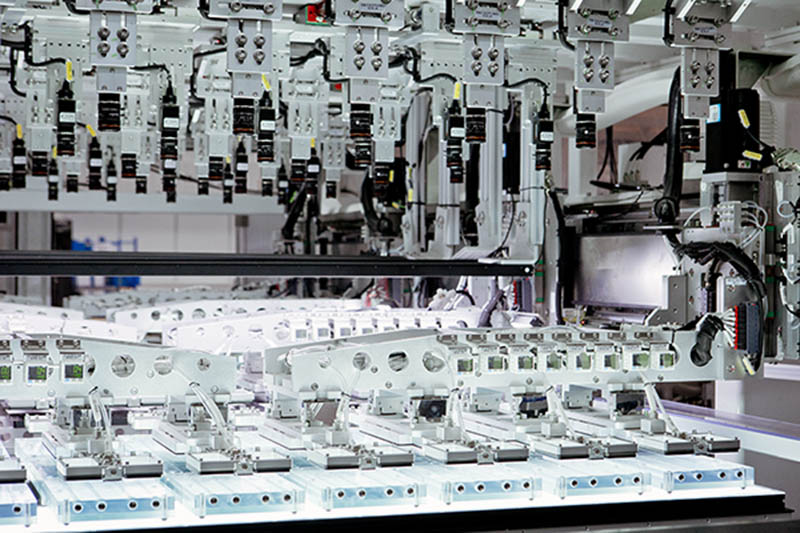

SVOLT Energy, founded only five years ago, is in the TOP 10 of installed global EV battery capacity in both 2021 and the first half of 2022. Such a proud achievement is largely based on its strong battery technology innovation capability, especially the innovation and continuous upgrade evolution of electrode stacking process technology and electrode stacking manufacturing technology. The stacking efficiency of the first generation of electrode stacking technology is 0.6 sec/layer, the second generation is 0.45 sec/layer, while the third generation of "Fly Stacking", with an efficiency of 0.125 sec/layer, has rivaled or even surpassed the electrode winding process, and is in the absolute leading position in the track of stacked cells.

The core technology of "Fly Stacking" that allows SVOLT Energy to significantly improve stacking efficiency is the shift from "single electrode cutting and stacking" to "multiple electrodes cutting and stacking". Multiple electrodes are cut and stacked at the same time on one machine to achieve more efficient output and double the efficiency with almost no change in the cost of a single machine.

In addition, the third generation of "Fly Stacking" technology also integrates battery electrode unwinding, cutting, hot pressing, CCD online monitoring and HI-POT online monitoring to achieve full inspection of all single electrodes.

Picture 2. SVOLT Energy Fly Stacking Machine

Thanks to the continued innovation and application of top battery cell manufacturers in the electrode stacking process for prismatic cells, the electrode stacking process is expected to be used on a large scale in prismatic cells in the future and to overtake the electrode winding process to become mainstream.

WinAck Group can provide a full range of battery electrode stacking solutions from laboratory production, pilot production to mass production. Come by, contact us for a solution that can help you succeed. For better batteries, Win & Ack!