The pouch cell sorting machine can automatically read battery code, test voltage and internal resistance, and then sort pouch cells into the matching channels based on the measured OCV/IR.

Model:

WA-AS-M6SIBattery type:

Pouch cellBattery feeding method:

Manual feedingTesting and grading items:

OCV/IRProduct Detail

Automatic Pouch Cell Sorting Machine

Li ion Cell Sorting Machine with Battery OCV/ACIR Tester

Product overview:

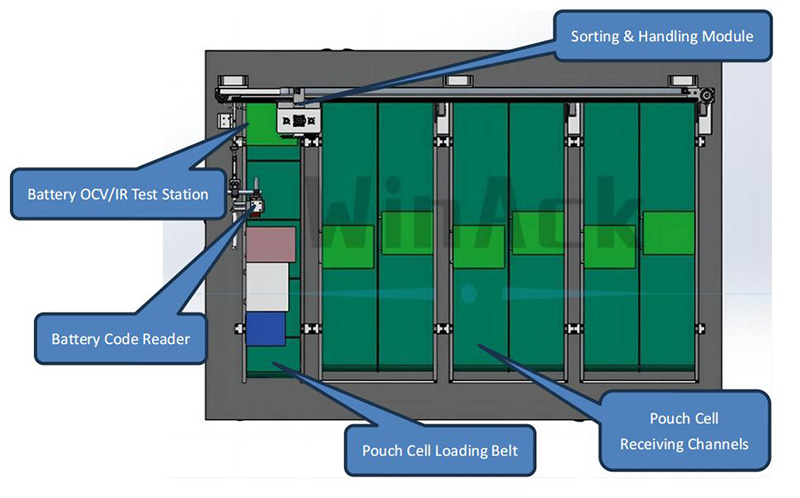

As a professional li ion cell sorting machine, the pouch cell sorting machine mainly consists of a pouch cell feeding belt module, a battery barcode/QR code reader, an OCV/IR test station, an automatic sorting and handling module, and a receiving channels module, etc.

The loading and unloading of pouch cells need to be completed manually, and the other steps are automatically completed by the pouch cell sorting machine. The brief process is: First, the pouch cells are manually placed on the feeding belt. Second, the feeding belt automatically sends the pouch cells to the battery code scanning area for barcode/QR code reading. Third, the loading belt sends the pouch cells to the battery OCV/IR test station for voltage and internal resistance testing, and binds the OCV/IR test data with the battery code data. Fourth, after the OCV/ACIR test is completed, the pouch cell sorting software will automatically determine the grade of the pouch cell according to the OCV/IR range set in each receiving channel, and the pouch cell is automatically assigned to the receiving channel corresponding to the matching grade by the unloading manipulator. Finally, the pouch cells are manually taken out from the receiving channels and placed into the corresponding containers.

Scope of application:

The automatic pouch cell sorting machine is suitable for automatic testing, sorting and grading of open circuit voltage and AC internal resistance of pouch cells.

The number of sorting channels and applicable pouch cell battery size range can be customized according to requirements.

Features:

1) Wide range of compatibility

The test probe module of the pouch cell sorting machine is adjustable, different types of pouch cells can be tested.

2) Simple operation and easy use

The automatic pouch cell sorting machine is equipped with an industrial PC, monitor and professional PC operating software. The machine operation is easy to learn and use, making pouch cell grouping and pre-matching simple and efficient.

3) High test accuracy

The automatic pouch cell sorting machine is equipped with a high-precision battery OCV/IR tester with high test accuracy, the HIOKI BT3561A is trustworthy.

4) Simple structure and easy maintenance

The pouch cell sorting machine is modularly designed, and the entire mechanical structure layout is simple and clear, which makes operation and maintenance very simple.

5) Four-wire measurement

The battery OCV/ACIR test is a four-wire measurement with high test accuracy.

6) Test data is traceable

The equipped battery code reader can bind the OCV/ACIR test data with pouch cell code data one by one, and the test data is traceable. Test data is automatically saved to the database and can be viewed and exported.

Technical Specifications of Automatic Pouch Cell Sorting Machine

|

Product name |

Pouch Cell Sorting Machine |

|

Product model |

WA-AS-M6SI |

|

Number of sorting channels |

6 Channels (5 OK Channels + 1 NG Channel) |

|

Sorting efficiency |

10~12PPM |

|

Applicable pouch cells (Customizable) |

Customized to specific requirements. |

|

Battery cells loading method |

Manual feeding to the feeding area. |

|

Battery tester |

Hioki BT3561A |

|

Battery cell testing and grading items |

OCV/IR |

|

Measurement of Internal resistance (IR) |

Test range: 0~60mΩ Test accuracy: ±0.5%rdg Test resolution: 0.1mΩ |

|

Measurement of Open circuit voltage (OCV) |

Test range: 0~20V Test accuracy: ±0.015%rdg Test resolution: 0.1mV |

|

Operation and control module |

Industrial PC and monitor |

|

Machine failure rate |

≤2% |

|

Possibility of damaging the cells |

≤0.1% |

|

Battery code reader |

Keyence SR-X100W |

|

Compatible with barcodes and QR codes |

|

|

AC input power (Customizable) |

Single-phase 220VAC±10% / 50Hz |

|

Power: 1000W |

|

|

Compressed air pressure |

0.5~0.8MPa |

|

Size(W*D*H) |

2000*1400*1865mm |

|

Weight |

About 400kg |

Figure 1. Mechanical Layout Diagram of Pouch Cell Sorting Machine

* Reference picture (Picture just as reference, please in kind prevail)

Figure 2. Automatic Pouch Cell Sorting Machine

* Reference picture (Picture just as reference, please in kind prevail)