This high voltage battery cycler is a regenerative battery charger and discharger with powerful test functions and capabilities, suitable for testing batteries of Electric Vehicles, Electric Buses and Energy Storage Systems.

Model:

WA-BTS-RJ1000V1000A1CH1000kWTest channels:

12CH/Cabinet (Customizable)Voltage range/CH:

100V~1000V (Customizable)Voltage accuracy:

±(0.05%FS+0.05%RD)Current range/CH:

±1000A (Customizable)Current accuracy:

±(0.05%FS+0.05%RD)Product Detail

High Voltage Battery Cycler

Battery Charger and Discharger

Product description:

This high voltage battery cycler is a professional battery charger and discharger with rich charge and discharge modes, powerful protection functions, powerful test functions, and powerful test capabilities, etc. The included user-friendly operating software makes the use of the high voltage battery cycler easy.

This battery charger and discharger is a regenerative battery cycler, the discharged electric energy can be fed back to the AC power grid, reducing energy waste and saving a lot of electricity costs.

Scope of application:

This regenerative battery charger and discharger is suitable for performance testing, life testing, aging testing and EOL testing of battery packs such as electric vehicles, electric buses, and energy storage systems, etc.

It is a necessary battery cycler for battery pack research and development, quality testing, SOC testing and SOC adjustment, etc.

Main test items:

1. Battery pack capacity test.

2. Battery pack charge/discharge performance test.

3. Battery pack charge/discharge efficiency test.

4. Battery pack charge retention and recovery ability test.

5. Battery pack cycle life test.

6. Battery pack temperature characteristics test.

7. Battery pack DC internal resistance test.

8. Battery pack pulse charge/discharge test.

9. Battery pack working condition simulation test.

10. Battery pack over-charge and over-discharge rate affordability test.

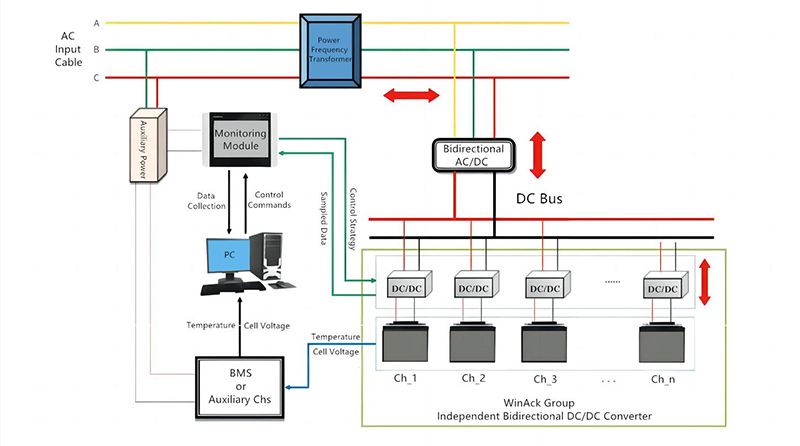

System Topology:

Figure 1. System Topology of WinAck High Voltage Battery Cycler

Features:

1. Regenerative design, using a common DC bus topology, energy conversion between DC channels can be achieved. And, battery discharge energy is preferentially regenerated between DC channels.

2. Regenerative design, if the DC channels cannot be balanced, the extra battery discharge energy will be regenerated to the AC power grid, which saves power and test costs.

3. The power control scheme of DSP&IGBT is adopted to achieve high-speed and high-precision control of electric energy.

4. The margin and timely power control algorithm ensures the stable and reliable operation of battery charger and discharger.

5. The output voltage range, current range, and power range can be freely set, and it is compatible with battery packs of various specifications and models.

6. AC input adopts adaptive technology and does not need to distinguish the phase sequence of the AC power grid.

7. Advanced software phase locking control technology, THD≤5%.

8. Scan the QR code to automatically bind the test process file, and scan the QR code to automatically start testing, avoiding manual errors and improving testing efficiency.

9. Supports automatic judgment of unqualified batteries to improve testing efficiency.

Technical Specifications of High Voltage Battery Cycler

|

Product name |

Battery Charger and Discharger |

||

|

Product model |

WA-BTS-RJ1000V1000A1CH1000kW |

||

|

Product type |

Regenerative type |

||

|

Regeneration efficiency |

≤93% (Full load) |

||

|

Energy regeneration features |

a) Battery discharge energy is preferentially regenerated between DC channels. b) If the DC channels cannot be balanced, the extra battery discharge energy will be regenerated to the AC power grid. |

||

|

AC Input Side |

|||

|

AC input power |

Voltage: 380VAC±10% Frequency: 50Hz±2Hz (Customizable) |

a) Three-phase five-wire power distribution system; b) Grounding resistance ≤5Ω. |

|

|

Power factor |

≥99% |

Full load |

|

|

The Harmonic Distortion |

THD≤5% |

Full load |

|

|

AC input protections |

AC power grid under-voltage protection |

|

|

|

AC power grid over-voltage protection |

|

||

|

AC power grid over-current protection |

Includes circuit breaker over-current protection. |

||

|

AC power grid over-load protection |

|

||

|

AC power grid input phase loss protection |

|

||

|

AC power grid frequency exception protection |

|

||

|

Transformer over-temperature protection |

|

||

|

Lightning protection |

|

||

|

Anti-islanding effect protection |

|

||

|

DC Output Side |

|||

|

Output channel |

No. of channels |

1 channels/cabinet |

Customizable |

|

Channel control mode |

Independent control of each channel |

|

|

|

Detection and Sampling |

Four-wire measurement |

|

|

|

Voltage/CH |

Charge range |

DC: 0V~1000V |

Customizable |

|

Discharge range |

DC: 1000V~100V |

Customizable |

|

|

Accuracy |

±(0.05%FS+0.05%RD) |

Customizable |

|

|

Resolution |

0. 1mV |

|

|

|

Current/CH |

Range |

DC: ±1000A |

Customizable |

|

Accuracy |

±(0.05%FS+0.05%RD) |

Customizable |

|

|

Resolution |

0. 1mA |

|

|

|

Maximum power/CH |

1000kW |

|

|

|

Maximum power/Cabinet |

1000kW |

|

|

|

Current rise time |

≤40ms |

10%~90% (Battery load) |

|

|

Current switch time |

≤80ms |

-90%~+90% (Battery load) |

|

|

Data collection interval |

≤10ms |

Includes current and voltage values. |

|

|

DC output protections |

Under-voltage protection |

|

|

|

Over-voltage protection |

|

||

|

Short-circuit protection |

|

||

|

Over-temperature protection |

|

||

|

Reverse connection protection |

|

||

|

Over-current protection |

|

||

|

Channel communication exception protection |

Automatically disconnect output if communication exception occurs. |

||

|

Power outage protection |

Automatically disconnect contactor during power outage. |

||

|

Emergency stop protection |

Includes emergency stop button. |

||

|

Other Parameters |

|||

|

Heat dissipation |

Air forced cooling |

|

|

|

IP Rating |

IP20 |

|

|

|

Sound |

≤75dB |

Measured from 1 meter away. |

|

|

Lightning protection level |

Level 2 |

|

|

|

AC cable lead-in method |

Top lead-in |

Customizable |

|

|

DC cable lead-out method |

Bottom lead-out |

Customizable |

|

|

Output cable |

Copper cable with tinned copper nose terminals |

|

|

|

BMS communication interface |

Each channel contains one CAN communication |

Each channel is configured with one 12V power supply. |

|

|

Cabinet color |

WinAck standard cabinet colors |

Customizable |

|

|

Reference dimensions |

W2940*D1140*H1900mm |

Subject to actual situation. |

|

|

Usage Environment Requirements |

|||

|

Altitude |

≤1000m |

|

|

|

Working temperature |

- 10℃~45℃ |

|

|

|

Relative humidity |

≤90%RH |

Non-condensing |

|

|

Storage temperature |

-20℃~50℃ |

|

|

|

Installation environment |

a) No strong vibration and impact; b) No strong electromagnetic interference. |

a) The intensity of external magnetic field induction shall not exceed 0.5m; b) The vertical slope of the installation should not exceed 5%. |

|

|

Usage environment |

a) No explosive hazardous media; b) Does not contain harmful substances that corrode metal and damage insulation; c) Does not contain conductive media; d) Mold is not allowed. |

|

|

Software Functions of Battery Charger and Discharger

|

Items |

Function description |

Remarks |

|

Database type |

MYSQL |

|

|

Data storage interval |

0.1S~9999S |

Configurable |

|

Nested Loop function |

Max. support 5 layers |

Hierarchical display of process flow. |

|

Editable number of steps |

Max. 9999 |

|

|

Number of cycles |

1~9999 |

|

|

DBC file parsing function |

Supports importing and editing of standard format DBC files |

|

|

Working condition simulation function |

Supports import of EXCEL working condition files |

Contains current working condition files and power working condition files; time and moment are optional. |

|

Charge mode |

Constant current charge |

If you have any other charge mode requirements, please consult us. |

|

Constant voltage charge |

||

|

Constant current to constant voltage charge |

||

|

Constant power charge |

||

|

Constant resistance charge |

||

|

Power follower |

||

|

Current follower |

||

|

Discharge mode |

Constant current discharge |

If you have any other discharge mode requirements, please consult us. |

|

Constant voltage discharge |

||

|

Constant power discharge |

||

|

Constant resistance discharge |

||

|

Power follower |

||

|

Current follower |

||

|

Cut-off condition (Jump condition or if condition) |

Working step time |

a) BMS data conditions require BMS to upload relevant data to be valid. b) If you have any other cut-off condition requirements, please consult us. |

|

Voltage |

||

|

Current |

||

|

Capacity (Total capacity, charging capacity, discharging capacity) |

||

|

Maximum cell voltage |

||

|

Minimum cell voltage |

||

|

Maximum cell temperature |

||

|

Cell voltage difference |

||

|

Cell temperature difference |

||

|

SOC |

||

|

Global control conditions |

Output voltage range |

BMS data conditions require BMS to upload relevant data to be valid. |

|

Current range |

||

|

Power range |

||

|

Cell voltage range |

||

|

Cell temperature range |

||

|

Cell voltage difference range |

||

|

Cell temperature difference range |

||

|

Unqualified battery judgment conditions |

Working step capacity |

It is optional to continue to the next work step or stop testing after being judged as unqualified. |

|

Total capacity |

||

|

End current |

||

|

Battery voltage |

||

|

Working Step energy |

||

|

Battery voltage difference |

||

|

Battery temperature difference |

||

|

SOC |

||

|

Software protections |

Output limit protection |

The output voltage, current and power range can be set. |

|

BMS data anomaly protection |

Including cell voltage, cell temperature, cell voltage difference, cell temperature difference, etc. |

|

|

Communication abnormality protection |

a) PC communication abnormality protection; b) BMS data abnormality protection. |

|

|

Abnormal power outage protection |

Support work step continuation function. |

|

|

Voltage over range protection |

When the voltage is out of range, the work step cannot be performed. |

|

|

Reverse connection protection |

When the connection is reversed, the work step cannot be performed. |

|

|

Data output |

Support single channel data export. |

|

|

Export data in batches. |

|

|

|

Export content is optional. |

|

|

|

Supports curve graph export. |

|

|

|

Supports exporting after data filtering. |

|

|

|

Data list content |

Detailed data list |

|

|

Cycle list |

|

|

|

Work step statistics list |

|

|

|

Log file |

|

|

|

Test process |

|

|

|

Test report |

|

|

|

Curve graphics |

|

|

|

Permission management |

Supports three-level permission management functions of super administrator, test administrator, and test operator. |

|

|

MES uploading function |

Upload data to MES as required. |

Optional |

|

Scan code function |

Scan the barcode or QR code to automatically start the test. |

We can set whether to enable this function. |

|

Supports automatic binding test process by scanning barcode or QR code. |

Automatically bind the test process to the battery pack coding rules and automatically start the test. |

|

|

LAN function |

Supports automatic synchronization of test process files between multiple PCs in the LAN. |

A separate server is required. |

|

Supports searching test data between multiple PCs in the LAN. |

Test data between different PCs can be quickly searched, and scan code search is supported. |

|

|

Test result judgment |

Supports automatic judgment of unqualified batteries. |

Unqualified conditions can be set freely and test results are automatically generated. |

|

DCIR test |

Support |

Test parameters can be set. |

|

Support database migration |

Support |

|

Reference Standards:

1) GB/T 18386.1-2021 Test methods for energy consumption and range of electric vehicles—Part 1: Light-duty vehicles

2) GB/T 18386.2-2022 Test methods for energy consumption and range of electric vehicles—Part 2: Heavy-duty commercial vehicles

3) GB/T 31484-2015 Cycle life requirements and test methods for traction battery of electric vehicle

4) GB/T 31486-2015 Electrical performance requirements and test methods for traction battery of electric vehicle

5) GB 38031-2020 Electric vehicles traction battery safety requirements

6) GB/T 18385-2005 Electric vehicles Power performance Test method

7) GB/T 31467.1-2015 Lithium-ion traction battery pack and system for Electric vehicles—Part 1: Test specification for High power applications

8) GB/T 31467.2-2015 Lithium-ion traction battery pack and system for Electric vehicles—Part 2: Test specification for High energy applications

Figure 2. Battery Charger and Discharger

* Reference picture (Picture just as reference, please in kind prevail)