The mobile power bank is a portable miniature energy storage system that can be carried by individuals, and is mainly provide emergency charging for mobile electronic devices, such as mobile phones, tablets, and laptops, especially in situations where there is no external power supply.

The mobile power bank is mainly composed of battery cells, a PCBA board, a DC-DC voltage converter and an outer casing.

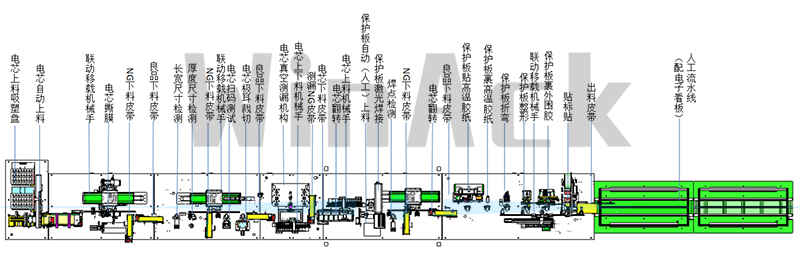

In this solution, the battery cell uses a pouch cell. The main process flow of the mobile power bank battery pack assembly line is as follows:

1) Preprocessing of pouch cell

The mobile power bank battery pack production line can realize automatic feeding, positioning, leveling, barcode scanning, OCV/IR testing, tabs cutting and tail gluing of pouch cells.

2) Manual installation

Manually install the bottom shell into the fixture, install the switch, and install the PCBA board.

3) Automatic fixing of PCBA

The power bank assembly line automatically locks the screws of the PCBA board, automatically attaches the bottom case and automatically attaches the double-sided tape.

4) Installation and laser welding of pouch cell

The power bank battery pack assembly line automatically puts the pouch cell into the bottom case, the TOP surface of the pouch cell is covered with foam, scans the code, PCBA laser welding and welding connection inspection.

5) Semi-finished product inspection

The laser welding defect is eliminated, the semi-finished product is tested, the NTC is fixed, and the upper cover of the shell is placed.

6) Installation of the upper cover of the shell

The upper cover of the shell is locked with screws, the shell is laser marked and SN burned, and decorative pieces are attached.

Advantages of the mobile power bank battery pack assembly line:

1) Flexibility

The power bank assembly line is composed of multiple single machines, and each machine is equipped with an independent loading and unloading system.

The power bank battery pack assembly line can be operated as a whole line, or it can be switched to single machines to run independently.

2) Strong compatibility

The mobile power bank production line can be compatible with different sizes of pouch cells, and one production line can produce multiple specifications and models of mobile power banks.

3) Visual inspection

The positioning of the battery is realized automatically through visual inspection, which greatly reduces the time for manual adjustment.

4) Smart manufacturing

The mobile power bank battery pack assembly production line is equipped with MES system and ESOP to realize the monitoring of the entire production line and grasp the production quality and production data in real time.

WinAck Group can provide production solutions for cylindrical cell battery modules and packs, pouch cell battery modules and packs, and prismatic cell battery modules and packs, which are based on the customer's technical requirements. Come by, contact us for a solution that can help you succeed. For better batteries, Win & Ack!