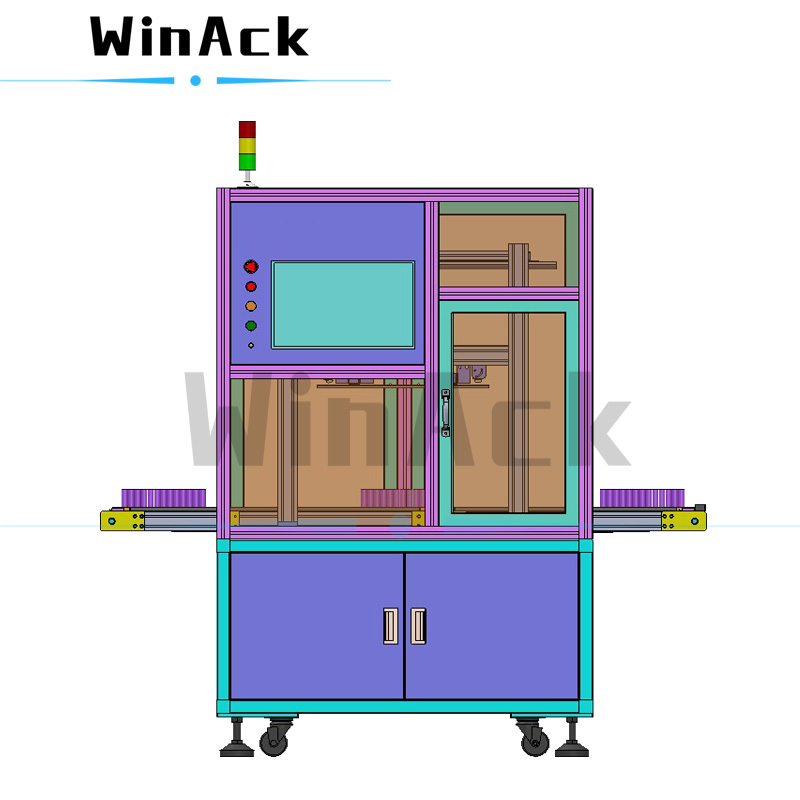

The cylindrical battery cell automated optical inspection machine can automatically inspect the battery polarity and check whether it is the same as the designed series-parallel combination.

Model:

WA-AOI-A5035Battery type:

Cylindrical cellInspection items:

Battery positive and negative polarity inspectionOrigin:

Made in ChinaDelivery time:

7~15 days (Negotiable)Warranty:

One year warranty with lifetime supportProduct Detail

Product overview:

The battery automated optical inspection system is one of the optional equipment for the cylindrical battery pack assembly line. Before installing the busbar for spot welding, first check whether the battery polarity of each cell on the battery cell holder meets the design requirements to avoid the situation where the positive and negative poles of the cell are reversed.

Scope of application:

The battery automated optical inspection system is suitable for the positive and negative polarity inspection of the cylindrical battery cell module before assembling the busbar.

Features:

1) The battery automated optical inspection system can perfectly replace manual inspection, with a false positive rate of 0%.

2) The programming is simple, and the judgment standard can be preset according to the series and parallel design of the battery module.

3) The battery automated optical inspection system checks and judges whether it is OK according to the preset standard, and it is easy to use.

4) If the battery cell is installed in the wrong direction, it will be automatically judged as NG, and the direction needs to be adjusted manually.

5)The battery AOI system can be used independently as a stand-alone equipment, or it can be connected to a cylindrical battery pack assembly line for use.

Technical specifications

|

Product name |

Battery Automated Optical Inspection Machine |

|

Product model |

WA-AOI-A5035 |

|

Inspection items |

Battery positive and negative polarity inspection |

|

Maximum inspection range |

500mm*350mm (Customizable) |

|

CCD lens object distance |

610~710mm |

|

Inspection time |

About 3~4S |

|

Ambient temperature |

-10~+35℃ |

|

Air humidity |

<90%RH |

|

Power supply |

Single-phase AC220V±10% / 50Hz (Customizable) |

|

Power consumption: ≤500W |

|

|

Size(W*D*H) |

About 1780*1000*1940mm |

|

Weight |

About 300kg |