The prismatic cell laser welding machine is professionally designed for prismatic cell tab welding, prismatic cell top cap sealing, prismatic cell seal pin welding and large cylindrical cell welding.

Model:

WA-LW-RS3000GS-PLaser type:

CW Fiber LaserLaser welding workstation:

Four-axis Electric Gantry WorkstationLaser welding applications:

Prismatic Cell Laser WeldingMoving Stroke:

X800*Y600*Z400mm (Customizable)Product Detail

Prismatic Cell Laser Welding Machine | Tab Welding

Prismatic Cell Top Cap Sealing and Seal Pin Welding

Product Overview:

The prismatic cell laser welding machine is a professional battery cell welder developed and designed for the battery cell assembly process, specifically for the laser welding and sealing of prismatic cells and cylindrical cells.

The prismatic cell laser welding machine is mainly composed of CW fiber laser, laser swing welding head, industrial PC, monitors, monitoring CCD, positioning CCD, height measuring sensor, inert gas blowing device, laser welding workstation, prismatic cell laser welding JIGs, dust collector (optional) and water chiller, etc.

Scope of Application:

The prismatic cell laser welding machine is mainly used for the prismatic cell tab welding, prismatic cell seal pin welding, prismatic cell top lid sealing, prismatic cell current collector welding, prismatic cell top cap sealing, cylindrical cell top cap sealing, cylindrical cell current collector welding and cylindrical cell seal pin welding, etc.

Features:

1) Well-known brand of CW fiber laser

This prismatic cell laser welding machine is equipped with well-known brand of CW fiber laser, which is highly suitable for laser welding and sealing in the prismatic cell assembling procedure. The standard configuration brand is GW Laser. In addition, Raycus Laser, Maxphotonics Laser and IPG Photonics Laser are optional brands.

2) Strong welding capability & High welding flexibility

The CW fiber laser equipped in the prismatic cell laser welding machine has strong welding ability and high welding flexibility. We can adjust the matching laser output power and laser welding speed according to the specific material and thickness. In addition, penetration welding or seam welding can be selected according to the specific laser welding application.

3) Professional prismatic cell laser welding control software

This battery cell welder is equipped with professional prismatic cell laser welding control software, and the laser welding process is simple to set up. After saving the prismatic cell tab welding process, prismatic cell seal pin welding process, and prismatic cell top lid sealing process, it can be quickly switched, which is simple and easy to use.

4) A variety of laser welding trajectories are available

Prismatic cell laser welding supports a variety of welding trajectories such as straight line, circle, square, arc, etc. The welding trajectory of each welding area can be the same or different, and the laser welding power can also be the same or different. Therefore, this laser welding machine can meet different laser welding and sealing applications in the prismatic cell assembly procedure.

5) Equipped with high-precision height measuring sensor

The prismatic cell laser welding machine is equipped with a high-precision micro laser distance sensor with a repeatability of 30μm, which can measure the height of the laser welding head with high precision to achieve high-quality laser welding results.

6) Equipped with monitoring CCD

The prismatic cell laser welding machine is equipped with a monitoring CCD, which allows us to clearly see each laser welding process and achieve real-time tracking of the welding trajectory.

7) Equipped with positioning CCD

The prismatic cell laser welding machine is equipped with positioning CCD, it can realize automatic photography and automatic compensation of welding position deviation to avoid welding position deviation caused by prismatic cell size deviation.

8) Equipped with inert gas blowing device

The prismatic cell laser welding machine is equipped with an inert gas blowing device and a reserved inert gas input port. After connecting to nitrogen or argon, it can prevent welding oxidation and further improve laser welding quality and pass rate.

9) Equipped with laser welding JIGs

The prismatic cell laser welding machine is equipped with laser welding JIGs, it ensures close contact between welding workpieces, thus guaranteeing the quality of laser welding. And, the laser welding JIGs can be customized according to different sizes and shapes of battery cells.

Technical Specifications of Battery Cell Welder

|

Product name |

Prismatic Cell Laser Welding Machine |

|

|

Product model |

WA-LW-RS3000GS-P |

|

|

AC input power (Customizable) |

Three-phase 380VAC±10%/50Hz |

|

|

Compressed air gas input |

≥0.6MPa |

|

|

30 L/min |

||

|

Inert gas input (Not must-have) |

Nitrogen or Argon |

|

|

≥0.4MPa |

||

|

15 L/min |

||

|

Control mode |

Industrial PC & Monitor Control |

|

|

Welding track input method |

CNC programming or teaching method |

|

|

Welding software |

Professional prismatic cell laser welding software |

|

|

Laser welding JIGs |

Prismatic cell tab welding JIG |

|

|

Prismatic cell top cap sealing JIG |

||

|

Prismatic cell seal pin welding JIG |

||

|

Optional: Cylindrical cell welding JIG |

||

|

Prismatic Cell Laser Welding Workstation |

||

|

Moving stroke (Customizable) |

X-axis |

800mm |

|

Y1-axis |

600mm |

|

|

Y2-axis |

600mm |

|

|

Z-axis |

400mm |

|

|

Positioning speed |

X-axis |

≤500mm/s |

|

Y1-axis |

≤500mm/s |

|

|

Y2-axis |

≤500mm/s |

|

|

Z-axis |

≤500mm/s |

|

|

Positioning accuracy |

±0.05mm |

|

|

Repeated positioning accuracy |

±0.02mm |

|

|

Drive method |

Servo motor drive |

|

|

Placement environment requirements |

Flat, no vibration and shock |

|

|

Ground load requirements |

≥600kg/㎡ |

|

|

Laser Specifications |

||

|

Laser type |

CW fiber laser |

|

|

Average output power |

3000W |

|

|

Operating mode |

CW/Pulse |

|

|

Power adjustable range |

10%~100% |

|

|

Output laser wavelength |

1080±10nm |

|

|

Beam quality |

M2≤5 |

|

|

Modulation frequency |

30~5000Hz |

|

|

Power instability |

±1.5% |

|

|

Welding speed |

10~100mm/s |

|

|

Output fiber length |

10m |

|

|

Control mode |

RS232 |

|

|

Cooling method |

Water-cooling |

|

|

Operating water temperature range |

25±3℃ |

|

|

Operating environment temperature |

0~+40℃ |

|

|

Operating environment humidity |

10~95%RH |

|

|

Storage temperature |

-20~+60°C |

|

|

Kindly reminder: For reference only, actual specifications are subject to the laser manufacturer. |

||

Main Configurations of Prismatic Cell Laser Welding Machine

|

Items |

Specifications |

Brand |

QTY |

|

CW fiber laser |

3000W |

GW Laser |

1 |

|

Laser fiber |

10m |

GW Laser |

1 |

|

Laser welding head |

Laser swing welding head |

WSX |

1 |

|

Monitoring CCD |

Anti-flash |

WSX |

1 |

|

Welding workstation |

4-axis |

X800*Y1600*Y2600*Z400mm |

1 |

|

Servo motor |

/ |

INVT |

4 |

|

Industrial PC |

/ |

JF |

1 |

|

PC Monitor |

/ |

AOC |

1 |

|

Positioning CCD |

/ |

MindVision / Hikvision |

1 |

|

Height measuring sensor |

/ |

Panasonic |

1 |

|

Inert gas blowing device |

/ |

Customized |

1 |

|

Water chiller |

/ |

TEYU / BY |

1 |

|

Welding control system |

Battery laser welding software |

Customized |

1 |

|

Dust collector (Optional) |

/ |

Sengyoep |

1 |

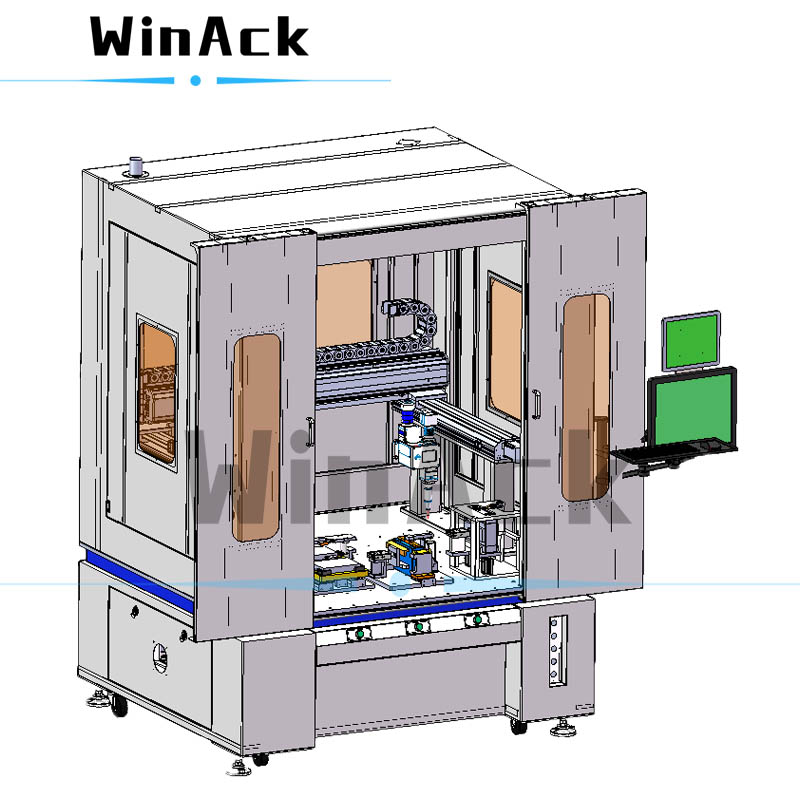

Figure 1. Prismatic Cell Laser Welding Machine

Kindly reminder: Picture just as reference, please in kind prevail.

Figure 2. Prismatic Cell Laser Welding | Tab Welding | Top Cap Sealing | Seal Pin Welding

Kindly reminder: Picture just as reference, please in kind prevail.