Pouch cell vacuum sealing machine is a professional pouch cell final vacuum sealing and edge cutting machine with good sealing effect and cell flatness, which can be used after the formation process.

Model:

WA-BSM-F390TSealing stamp width:

2~10mm (Available upon request)Sealing temperature:

Max. temperature: 250℃ (Customizable)Sealing thickness:

0.12~0.30mm (Customizable)Sealing time:

0~99.9sSealing head pressure:

0.3~ 0.6MPaProduct Detail

Pouch Cell Vacuum Sealing Machine

Final Sealing and Edge Cutting Machine

Product overview:

The pouch cell vacuum sealing machine is a professional vacuum sealer for pouch cell batteries, which adopts turntable type three-station design, with the functions of automatic vacuuming and air exhausting, bayonet piercing the air pocket exhausting, pouch film heat sealing and pouch film edge cutting, etc.

The vacuum chamber of pouch cell vacuum sealing machine has good vacuum retention, and its sealing temperature, pressure and time are adjustable. The pouch cell has high quality sealing effect and good flatness of the finished batteries.

Scope of application:

After the cell formation process, the pouch cell vacuum sealing machine can be used for the final sealing and edge cutting of the pouch cell.

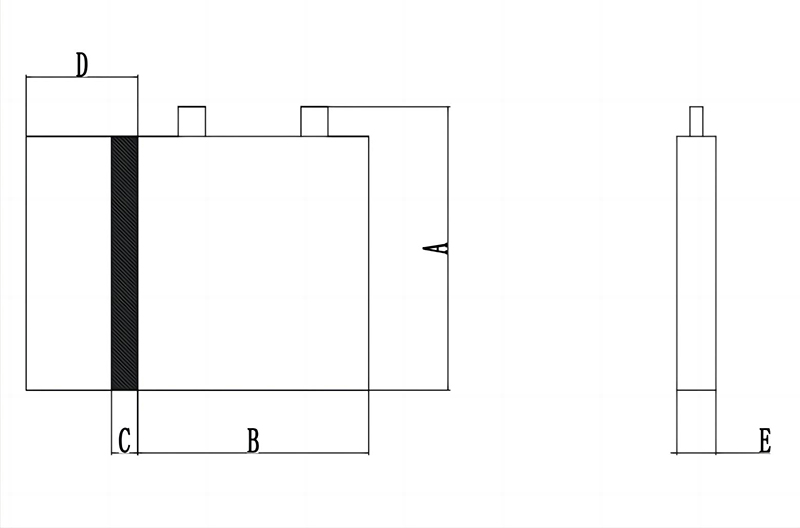

Kindly reminder: The following pouch cell dimensions are for reference only and can be customized according to actual size and requirements.

Table 1. Dimensions of incoming pouch cells for reference

|

NO. |

Items |

Dimension |

Accuracy |

|

A |

Main body length |

150~240mm (Customizable) |

±0.2mm |

|

B |

Main body width |

100~170mm (Customizable) |

- |

|

C |

Total length |

130~280mm (Customizable) |

- |

|

D |

Total width |

190~270mm (Customizable) |

- |

|

E |

Remaining edge |

5~15mm (Customizable) |

±1.0mm |

|

T |

Thickness |

3.0~12.0mm (Customizable) |

±0.3mm |

Brief working steps of the pouch cell vacuum sealing machine:

1. Manually place the pouch cell into the fixture at the cell loading and unloading station of the vacuum sealer machine.

2. The pouch cell is automatically rotated on the turntable and then arrive at the vacuum sealing station, which automatically completes the vacuuming and air exhausting, bayonet piercing the air pocket exhausting, pouch film heat sealing.

3. After the turntable rotates automatically, the pouch cell reaches the edge cutting station, and automatically completes the edge cutting of the pouch film.

4. The pouch cell reaches the cell loading and unloading station after the turntable rotates automatically, where the pouch cell is unloaded manually.

Features:

1) The pouch cell vacuum sealing machine is PLC controlled, HMI operated, and the sealing pressure and sealing time are adjustable.

2) The vacuum pumping system is equipped with an electrolyte separation drum, which can recycle electrolyte and significantly reduce environmental pollution.

3) The pouch cell vacuum sealing machine has an abnormal temperature alarm function. The vacuum sealer machine will only operate when the temperature reaches the set value to ensure the sealing quality.

4) The upper and lower chambers of the vacuum chamber are of concentric gantry structure to ensure sealing alignment and parallelism.

5) The lower chamber of the vacuum chamber is of detachable design, which is convenient to clean the residual electrolyte inside the chamber periodically and increase the service life of the pouch cell vacuum sealing machine.

6) The bayonet is designed to be easily detachable for maintenance and replacement.

7) The pouch film edge cutter is adjustable and easy to replace.

Technical specifications

|

Product name |

Pouch Cell Vacuum Sealing Machine |

|

Product model |

WA-BSM-F390T |

|

Sealing process |

Final sealing of aluminum laminate film after formation |

|

Operation efficiency |

2.5~3.0 PPM (Higher efficiency is customizable) |

|

Utilization rate |

≥98% |

|

Equipment failure rate |

≤2% |

|

Control method |

Touch Panel & PLC |

|

AC input power |

Three-phase 380VAC±10% / 50Hz (Customizable) |

|

Power: 4.5kW |

|

|

Input compressed air supply |

0.6~0.7MPa |

|

Vacuum source |

≤-0.095MPa, 20L/min. Kindly reminder: The vacuum pump is optional. |

|

Dimensions |

W1520*D1520*H1900mm |

|

Weight |

About 1300kg |

|

Specifications of the pouch cell vacuum final sealing station |

|

|

Vacuum Level |

-0.095MPa (Adjustable) |

|

Qualified rate of vacuuming |

≥99.8% |

|

Sealing stamp width |

2~10mm (Available upon request) Accuracy: ±0.1mm |

|

Sealing head length |

360mm (Customizable) |

|

Sealing head parallelism |

±0.008mm |

|

Sealing thickness |

0.12~0.30mm (Customizable) |

|

Deviation of sealing thickness |

±0.007mm |

|

Sealing head pressure |

0.3~ 0.6MPa |

|

Sealing time |

0~99.9s |

|

Sealing temperature |

Max. temperature: 250℃ (Customizable) Accuracy: ±3℃ |

|

Sealing head material |

Brass & NAK80 |

|

Sealing effect |

Aluminum laminate film does not detach from each other, good sealing, flat surface, no wrinkles, no bubbles. |

|

Width of outer unsealed area |

0.35~1.00mm (Customizable) |

|

Width of inner unsealed area |

0.5~2.0mm (Customizable) |

|

Specifications of the pouch cell edge cutting station |

|

|

Width of edge cutting |

3.5~10.0mm (Customizable) |

|

Deviation of edge cutting |

±0.5mm |