Pouch cell sealer is an automatic heating sealer for pouch case with integrated top sealing, side sealing, Hi-Pot testing and corner sealing, which has good sealing quality and high productivity.

Model:

WA-BSM-TS260TSealing stamp width:

2~10mm (Available upon request)Sealing temperature:

Max. temperature: 250℃ (Customizable)Sealing thickness:

0.12~0.30mm (Customizable)Sealing time:

0~19sSealing head pressure:

0.3~ 0.6MPaProduct Detail

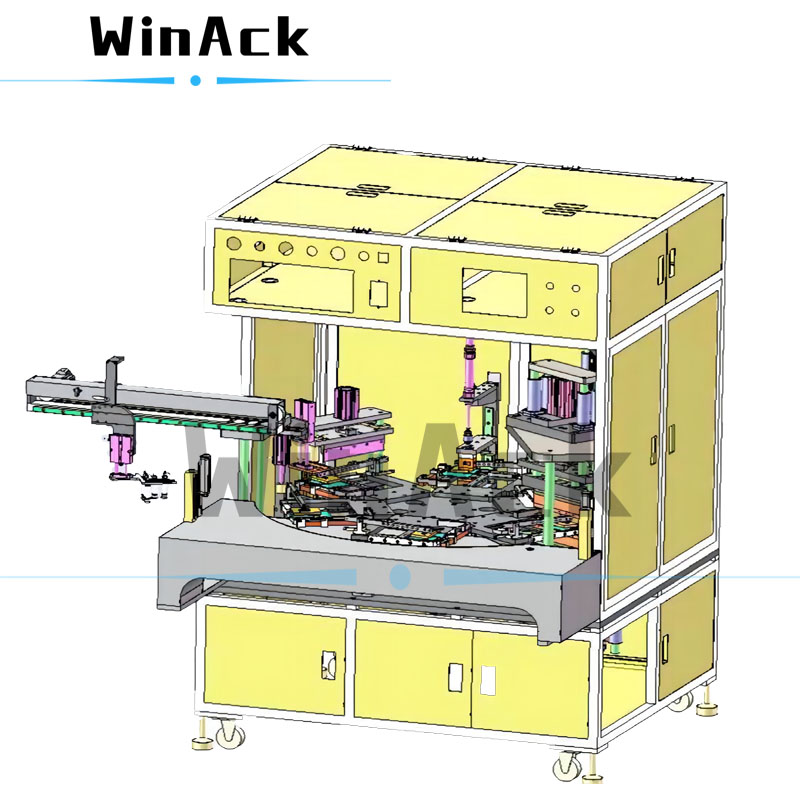

Pouch Cell Sealer

Automatic Heating Sealer for Pouch Case on Two Sides

Product overview:

This pouch cell sealer is an automatic heating sealer for pouch case with a turntable design that performs top sealing, side sealing, Hi-Pot testing and corner sealing of pouch cell batteries.

Scope of application:

After the electrode stacking process or electrode winding process is completed, and before the electrolyte injection process, the top sealing and side sealing of the pouch case are required. This pouch cell sealer is specially designed for this sealing process, with high sealing productivity and good sealing quality.

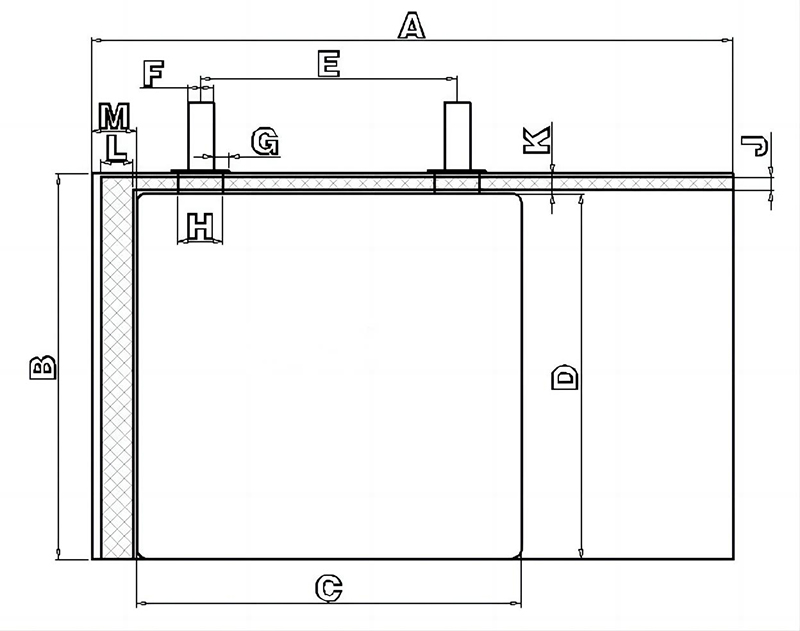

Kindly reminder: The following pouch cell dimensions are for reference only and can be customized according to actual size and requirements.

Table 1. Dimensions of incoming pouch cells for reference

|

NO. |

Items |

Dimension |

|

A |

Total width |

80~180mm (Customizable) |

|

B |

Main body height |

≤180mm (Customizable) |

|

C |

Main body width |

≤120mm (Customizable) |

|

E |

Center distance of tabs |

Depends on the process |

|

F |

Tabs width |

3~8mm (Customizable) |

|

J |

Top sealing width |

2.5~8.0mm (Customizable) |

|

L |

Side sealing width |

4.0~8.0mm (Customizable) |

Brief working steps of the pouch cell sealer:

1. Manually place the unsealed pouch cell into the fixture at the loading station and secure it with a fixed pressing fixture.

2. The pouch cell is automatically rotated on the turntable and then arrive at the top sealing station, which automatically completes the top sealing process.

3. After that, the pouch cell rotates automatically on the turntable to complete the side sealing process, Hi-Pot testing process, corner sealing process and unloading in turn.

Features:

1) After manual loading, pouch cell sealer can automatically complete top sealing, side sealing, Hi-Pot testing, corner sealing and unloading, with high automation and high production efficiency.

2) The sealing temperature, sealing pressure and sealing time of the pouch cell sealer can be adjusted to ensure good sealing quality and wide applicability.

3) The Hi-Pot test station can test whether there is a short circuit inside the pouch cell and strengthen the battery quality control.

4) The loading station of the pouch cell sealer is equipped with precisely positioned pouch cell jigs for easy and fast cell loading.

5) The front of the loading station is equipped with a safety light curtain to ensure safe operation.

Technical specifications

|

Product name |

Pouch Cell Sealer |

|

Product model |

WA-BSM-TS260T |

|

Sealing process |

Top and side sealing of pouch case before electrolyte injection |

|

Operation efficiency |

400PCS/H (Higher efficiency is customizable) |

|

Qualified rate |

≥99.8% |

|

Control method |

Touch Panel & PLC |

|

AC input power |

Single-phase 220VAC±8% / 50Hz (Customizable) |

|

Power: 4.5kW |

|

|

Input compressed air supply |

0.6~0.8MPa |

|

Dimensions |

W1250*D1000*H1750mm |

|

Weight |

About 600kg |

|

Specifications of the pouch cell sealing stations |

|

|

Top sealing head length |

230mm (Customizable) |

|

Top sealing stamp width |

2~10mm (Available upon request) Accuracy: ±0.1mm |

|

Side sealing head length |

230mm (Customizable) |

|

Side sealing stamp width |

2~10mm (Available upon request) Accuracy: ±0.1mm |

|

Sealing head parallelism |

±0.01mm |

|

Sealing thickness |

0.12~0.30mm (Customizable) |

|

Deviation of sealing thickness |

±0.007mm |

|

Sealing head pressure |

0.3~ 0.6MPa |

|

Sealing time |

0~19s |

|

Sealing temperature |

Max. temperature: 250℃ (Customizable) Accuracy: ±3℃ |

|

Sealing head material |

Brass H62 & NAK80 |

|

Sealing effect |

Pouch film does not detach from each other, good sealing, flat surface, no wrinkles, no bubbles. |