This pouch cell vacuum sealer is a simple heat sealer for pouch cell aluminum laminate film, which is pre-sealing after pre-vacuuming. It is a simple pouch cell assembly equipment.

Model:

WA-BSM-F300SSealing stamp width:

4~10mm (Customizable)Sealing temperature:

Max. temperature: 260℃ (Customizable)Sealing thickness:

0.19~0.30mm (Customizable)Sealing time:

0~99.9sSealing head pressure:

0.3~ 0.6MPaProduct Detail

Pouch Cell Vacuum Sealer

Heating Sealer for Pouch Cell Aluminum Laminate Film

Product overview:

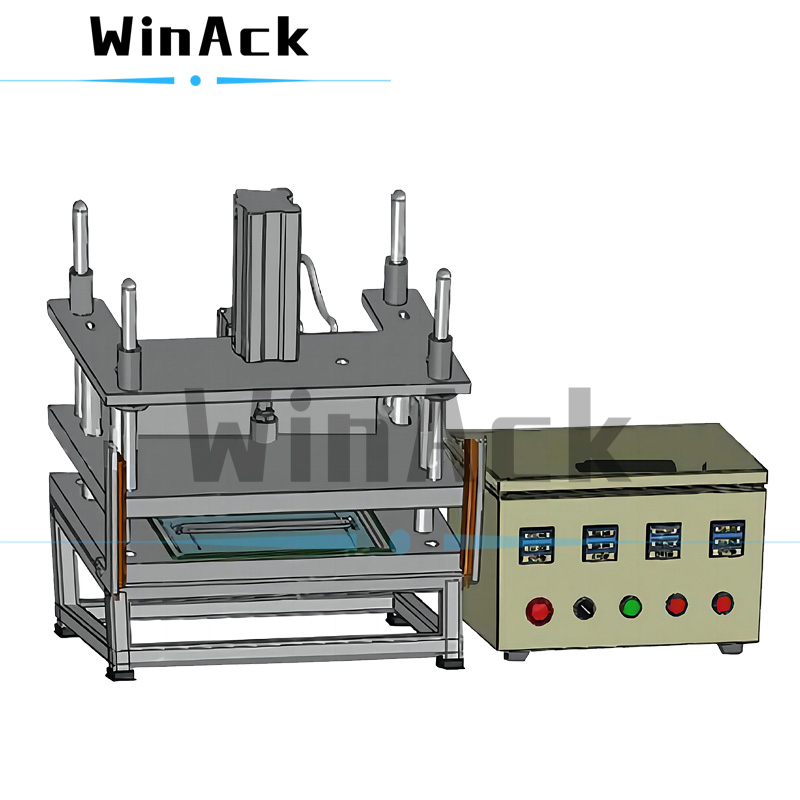

The pouch cell vacuum sealer is a simple design type of heating sealer for pouch cell batteries. It mainly consists of a vacuum chamber, a pneumatically controlled heat sealer module and a control cabinet. The aluminum laminate film of the pouch cell is sealed by heating and fusing, with good sealing effect and high fastness.

Scope of application:

After the battery electrolyte filling and vacuum standing process, the pouch cell vacuum sealer can be used to evacuate the air inside the pouch cell and then heat seal the pouch film. After this pre-sealing process is completed, the pouch cells will be ready for the battery formation process.

Kindly reminder: The following pouch cell dimensions are for reference only and can be customized according to actual size and requirements.

Table 1. Dimensions of incoming pouch cells for reference

|

NO. |

Items |

Dimension |

|

1 |

Length |

≤290mm (Customizable) |

|

2 |

Width |

≤350mm (Customizable) Kindly reminder: Air pocket included |

|

3 |

Thickness |

3~15mm (Customizable) |

Brief working steps of the pouch cell vacuum sealer:

1. The pouch cell is manually placed into the vacuum chamber and the upper and lower chambers are closed to form an airtight chamber.

2. The vacuum source pumps the air inside the chamber into a negative pressure state of -60KPa~-90KPa, so that the air inside the pouch cell is pumped away.

3. The heated top and bottom sealing heads are pressed onto the aluminum laminate film so that they are heated and fused together to seal the pouch cell.

4. After the heat seal is completed, the upper and lower chambers are opened and the pouch cell can be removed.

Features:

1) The control cabinet and the vacuum chamber of the pouch cell vacuum sealer are independent, and the vacuum chamber can be used in the glovebox alone, which does not occupy the internal space of the glove box and can improve the service life of the electrical components.

2) Heat sealing temperature, time, pressure and vacuum level can be preset according to the sealing process requirements of pouch film.

3) With abnormal temperature alarm function, the temperature is too low or too high will alarm to ensure the heat-sealing effect.

4) The upper chamber of the vacuum chamber is guided by four column linear bearings for accurate precision and good stability.

5) There are protective baffles around the vacuum chamber and light curtain protection in the feeding direction to ensure the safety of operators.

6) The pouch cell vacuum sealer is equipped with a PLC and text display, with programmable sealing process and easy operation settings.

Technical specifications

|

Product name |

Pouch Cell Vacuum Sealer |

|

Product model |

WA-BSM-F300S |

|

Sealing process |

Pre-sealing after electrolyte filling and vacuum standing process |

|

Operation efficiency |

100~250PCS/H |

|

Utilization rate |

≥95% |

|

Yield rate |

≥99% |

|

Control method |

Button Panel & PLC |

|

AC input power |

Single-phase 220VAC±10% / 50Hz (Customizable) |

|

Power: 1100W |

|

|

Input compressed air supply |

0.6~0.7MPa, 5L/min. |

|

Vacuum source |

≤-0.095MPa, 50L/min. Kindly reminder: The vacuum pump is optional. |

|

Dimensions |

W580*D450*H500mm |

|

Weight |

About 100kg |

|

Vacuum Level |

-0.06~-0.09MPa (Adjustable) |

|

Sealing stamp width |

4~10mm (Available upon request) Accuracy: ±0.1mm |

|

Sealing head length |

300mm (Customizable) |

|

Sealing thickness |

0.19~0.30mm (Customizable) |

|

Sealing head pressure |

0.3~ 0.6MPa |

|

Sealing time |

0~99.9s |

|

Sealing temperature |

Max. temperature: 260℃ (Customizable) Accuracy: ±2℃ |

|

Sealing head material |

Brass & NAK80 |

|

Sealing effect |

Pouch film does not detach from each other, good sealing, flat surface, no wrinkles, no bubbles. |