This dual-shaft planetary vacuum mixer is a professional lithium-ion battery slurry mixer machine for electrode slurry preparation process with uniform mixing and no pollution.

Model:

WA-MIX-E2LWorking volume:

2L (Customizable)Designed volume:

3.8L (Customizable)Mixing drum size:

φ180mm×150mm (Customizable)Orbital revolution speed:

0~65rpmOwn rotation speed:

0~100rpmDispersion speed:

0~7500rpmProduct Detail

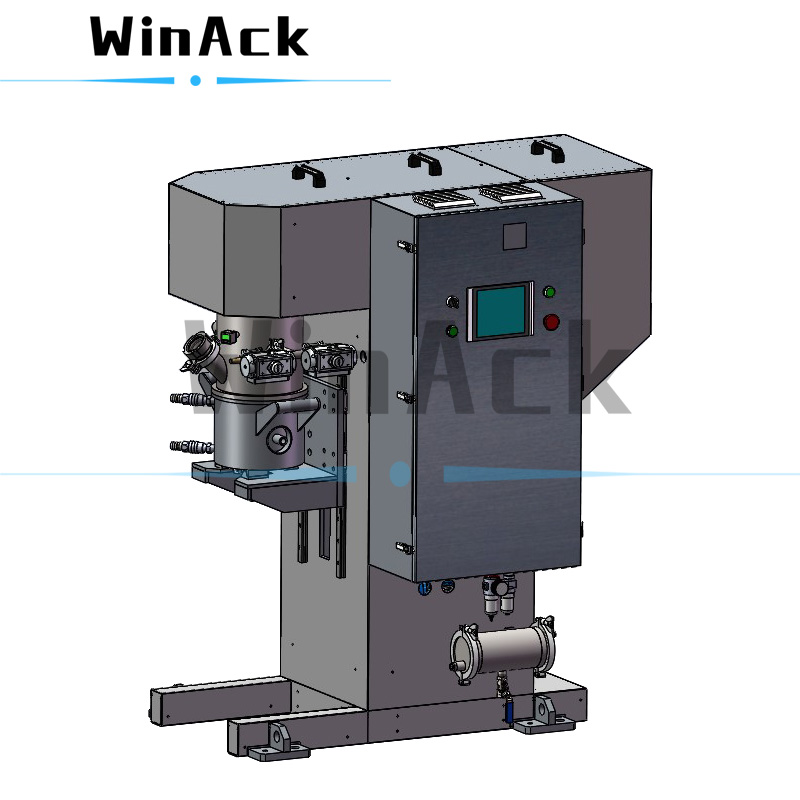

Dual-shaft Planetary Vacuum Mixer

Lithium-ion Battery Slurry Mixer Machine

Product overview:

This lithium-ion battery slurry mixer machine is a professional dual-shaft planetary vacuum mixer, which mainly consists of electric motors, sealing cover, mixing drum, mixing paddles, dispersion paddles, lifting mechanism and control system, etc.

The dual-shaft planetary motion way of mixing paddles and dispersion paddles rotating on its own and orbital revolution makes the battery materials carry out complex motion in the mixing drum and are strongly dispersed and squeezed to ensure the materials are fully dispersed and mixed.

|

Lithium-ion Battery Slurry Mixer Machine (Working volume can be customized) |

|

|

Product model |

Working volume |

|

WA-MIX-M150mL |

150mL |

|

WA-MIX-M250mL |

250mL |

|

WA-MIX-M500mL |

500mL |

|

WA-MIX-M1L |

1L |

|

WA-MIX-E2L |

2L |

|

WA-MIX-E5L |

5L |

|

WA-MIX-E10L |

10L |

|

For more product models, please click " Battery Slurry Mixer" to view or contact us. |

|

Scope of application:

The lithium-ion battery slurry mixer machine is suitable for battery electrode slurry preparation process and can perform a variety of high viscosity and high solid content battery electrode slurry mixing, viscosity range from 1,000 cps to 1 million cps.

Features:

1) High mixing speed

The twist-frame mixing paddles in the mixing drum rotates on its own while rotating in public, which can achieve the mixing effect in a short time.

2) Adjustable mixing speed, wide applicability

The lithium-ion battery slurry mixer machine can choose different speed according to different materials, different processes and different viscosities, with wide applicability.

3) Powerful safety protection

The dual-shaft planetary vacuum mixer has a strong safety protection function, equipped with safety chains to ensure operational safety.

4)Good sealing and vacuum performance

Good sealing of the battery slurry mixer, dynamic vacuum pressure: ≤-0.098Mpa, 24-hour holding pressure: ≤-0.085Mpa.

5) Accurate detection of material temperatures

The mixer is equipped with a temperature monitoring system and a water-cooling system to accurately measure the material temperature.

6) Anti-drop protection for mixing drum

The lifting motor of the mixing drum with self-locking function ensures that there will be no vacuum leakage caused by the automatic falling of the mixing drum during the mixing process.

7) Easy-to-clean mixing paddles

The type of stirring paddle is 90° twist frame type, which is cast in one time by precision mold, and then processed by CNC machine in three dimensions. Mirror polished surface, easy to clean.

Technical Specifications

|

Product name |

Lithium-ion Battery Slurry Mixer Machine |

|

Product model |

WA-MIX-E2L |

|

Working volume |

2L (Customizable) |

|

Designed volume |

3.8L (Customizable) |

|

Orbital revolution speed |

0~65rpm |

|

Own rotation speed |

0~100rpm |

|

Dispersion speed |

0~7500rpm |

|

Dispersion plate line speed |

0~18m/s |

|

Mixing drum |

l Size: φ180mm×150mm l Inner drum material: SUS304, mirror polishing treatment on inner and outer surface to ensure good roundness. l The upper flange plane of the mixing drum is sealed with the upper drum body by a silicone seal. l There is 1 DN20 discharge valve at the bottom of the mixing drum and 2 DN15 cooling water connections at the wall of the mixing drum. l The bottom of the mixing drum and the wall of the drum are with cooling water infusion to ensure the cooling effect of the mixed materials. |

|

Motors power |

l Power of mixing motor: 1.1kW. l Power of dispersion motor: 1.5kW. l Power of lift motor: 0.55kW. |

|

Upper drum body (Kettle cover) |

l Material: SUS304, mirror polishing treatment on inner and outer surface. l One Φ50 powder/liquid dosing port with quick opening/closing. l With one spotlight; with 2 small viewports, 1 spotlight hole and 1 observation hole. l One vacuum pressure gauge, one manual ball valve for vacuum extraction, one manual ball valve for vacuum release, and one spare φ25 quick-fit interface. |

|

Wall scraping paddle |

l The quantity is 1 group, the material of wall scraping paddle is SUS304 & Teflon. l The speed is the same as the orbital revolution speed. |

|

Mixing paddle |

l The quantity is 2 groups, the material of mixing shaft and mixing paddle is SUS304. l Mixing paddle: The type of mixing paddle is 90° twist frame type. |

|

Dispersion plate |

l The quantity is 2 groups, each group with 2 dispersion plates. l Material is SUS304, Lotus serrated structure. l The diameter is φ47; it can adapt to various high viscosity materials. |

|

Gap values for reference |

l The distance between mixing paddle and mixing paddle: 5+1.5 mm. l The distance between the mixing paddles and the bottom of the mixing drum: 4±1mm. l The distance between the mixing paddles and the drum wall of the mixing drum: 4±1mm. |

|

Lifting stroke |

≤250mm |

|

Sealing methods |

Dynamic seal: 2 sets of mechanical seal & Viton skeleton oil seal. Static seal: Viton O-ring. |

|

Vacuum performance |

Dynamic vacuum pressure: ≤ -0.098Mpa; 24 hours holding pressure: ≤ -0.085Mpa. |

|

Temperature measurement system |

l The temperature is measured at the wall of the mixing drum, and the temperature sensor is in direct contact with the material for temperature measurement. l Temperature display range: 0~200℃, measurement accuracy: ±1℃. |

|

Control System |

Control method: PLC and touch screen control. Vacuum start/stop, frequency and speed controls, temperature display, spotlight switch, mixing drum up/down, operation, emergency stop and other functional operations are all on the touch screen. |

|

Safety Protection |

l The mixing and dispersing system can only operate after the mixing drum has risen to the set position. l When the mixing and dispersing system fails, the lithium-ion battery slurry mixer will automatically stop and alarm. l When there is a vacuum in the dual-shaft planetary vacuum mixer, the mixing drum cannot be lowered and will alarm, and can only be lowered after the vacuum is discharged. l The battery slurry mixer can set the material temperature limit, and if the temperature is too high, it will alarm and stop. |

|

Materials |

l All materials in contact with the mixing materials are SUS304 stainless steel. l The mixer body is made of Q235 steel, and the outer surface is all wrapped with 1.2mm thickness stainless steel brushed plate. |

|

AC input power |

Three-phase 380VAC±10%, 50Hz±1Hz, Power: 3.15kW (Customizable) |

|

Vacuum source |

Pressure: -0.098Mpa, Tube interface: ¢10, Consumption: 3L/time |

|

Nitrogen source |

Pressure: 0.1~0.2Mpa, Tube interface: ¢10, Consumption: 3L/time |

|

Compressed air source |

Pressure: 0.4~0.6Mpa, Tube interface: ¢10, Consumption: 2L/min |

|

Cooling water |

Water temperature: <10℃, Pressure: 0.5Mpa, Tube interface: ¢10, Consumption: 25m³/h |

|

Dimensions |

W700*D1000*H1500mm |

|

Weight |

About 380kg |