The battery module stacking and pressing machine has adjustable pressing force and pressing stroke, and is one of the essential equipment in the prismatic cell lithium battery pack production line.

Model:

WA-MF-SL1100Pressing Stroke:

200~1100mm (Adjustable & Customizable)Pressing Force:

0~1000kg (Adjustable & Customizable)Pressing Mode:

Servo Motor Drive (High precision & High reliability)Control Mode:

Touchscreen & PLCProtection:

Pressing stroke & Pressing forceProduct Detail

Battery Module Fastening Machine

Battery Module Stacking and Pressing Machine

Product Overview:

The prismatic cell battery module stacking and pressing machine, also called battery module fastening machine, is one of the essential production equipment for prismatic cell battery pack production line.

First, manually stack the end plates, heat shields and prismatic cells to the lithium battery module stacking station, then press the pressing start button. Second, the PLC will control the force sensor to output a signal to the electric cylinder to tighten the battery module. When the pressing force or pressing stroke reaches our set value, the electric cylinder stops and the steel belt or PE belt can be added to the battery module manually. Finally, we press the reset button of the electric cylinder, the electric cylinder releases, and manually removes the tightened prismatic cell battery module.

Scope of Application:

The battery stacking pressing machine is suitable for prismatic cell battery module stacking and pressing process, and can adjust the pressing force and pressing stroke according to the specific battery module design.

Features:

1) Strong compatibility of battery modules

The battery module stacking and pressing machine is compatible with the mainstream prismatic cells on the market, and supports battery modules of different sizes. The compatible battery module length is 300~1000mm, the width is 100~300mm, and the height is 100~250mm.

2) Safe and reliable tightening process

The main press module of the prismatic battery pressing machine is equipped with a servo motor, an electric cylinder and a force sensor, which can achieve a high-precision and high-stability battery module pressing process. And, when the pressing force reaches the set upper limit, the red buzzer lights up to alarm, which can effectively prevent the battery module from being damaged.

3) Adjustable pressing stroke

The auxiliary press module of the prismatic cell battery module stacking and pressing machine is equipped with a stroke adjustment handle, which can quickly adjust the pressing stroke according to the size of the battery module.

Technical Specifications of Battery Module Fastening Machine

|

Product name |

Battery Module Stacking and Pressing Machine |

|

Product model |

WA-MF-SL1100 |

|

AC input power (Customizable) |

Single-phase 220VAC±10% / 50Hz Power consumption: ≤1500W |

|

Input compressed air |

0.5~0.6MPa |

|

Battery module type |

Prismatic cell battery module |

|

Compatible battery module sizes (Customizable) |

Length: 300~1000mm |

|

Width: 100~300mm |

|

|

Height: 100~250mm |

|

|

Specific applications |

Manual stacking & Automatic pressing to tighten the battery module. |

|

Control mode |

Touchscreen & PLC |

|

Pressing stroke range |

200~1100mm (Adjustable) |

|

Pressing force range |

0~1000kg (Adjustable) |

|

Protection function |

1) Real-time monitoring of the pressing distance. 2) When the pressing force reaches the set upper limit, the red buzzer lights up to alarm. |

|

Ambient temperature |

0~40℃ |

|

Ambient humidity |

≤90% (No condensation) |

|

Grounding type |

Direct grounding |

|

Operating place |

1) No pollution and strong electromagnetic interference. 2) The ground is flat and free of vibration and impact. 3) Area load-bearing rate: ≤200kg/m2. |

|

Noise |

≤80db |

|

Size |

W2155*D700*H1588mm |

|

Weight |

About 300 kg |

Main Configurations of Prismatic Cell Battery Stacking Pressing Machine

|

Serial number |

Spare Parts |

Brand |

|

1 |

Electric cylinder |

SENTO |

|

2 |

Force sensor |

DAY SENSOR |

|

3 |

Servo motor |

XINJE |

|

4 |

PLC |

XINJE |

|

5 |

Touchscreen |

XINJE |

|

6 |

Insulation module |

Custom made |

|

7 |

Cabinet |

WinAck |

|

8 |

Standard Parts |

YIHEDA |

Remarks: If the above brand components out of stock, we will change with same class ones instead without information to customer, thus not influence the delivery time. Hope for understanding!

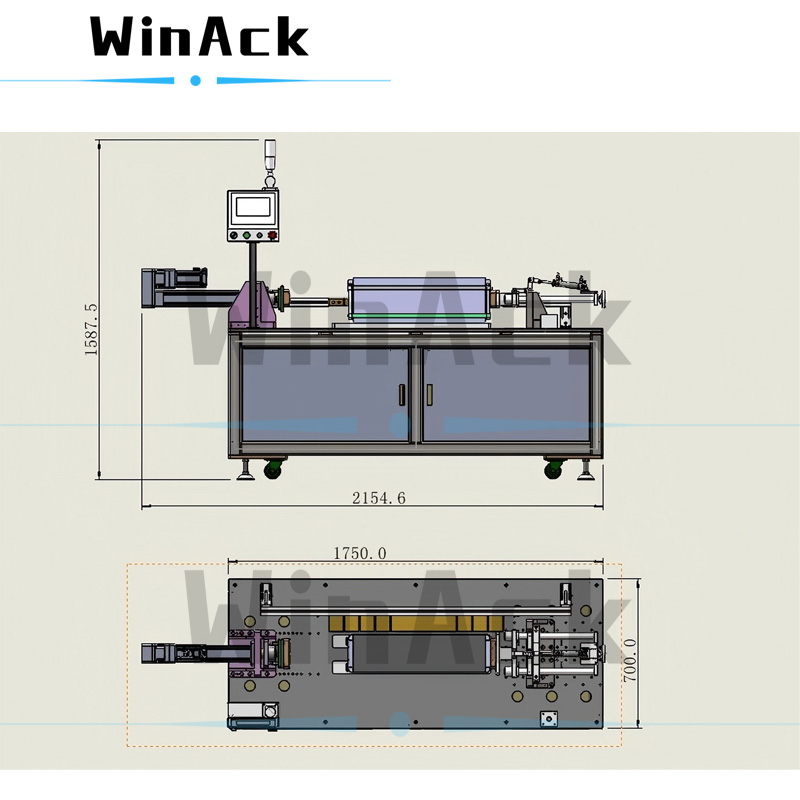

Figure 1. Prismatic Cell Lithium Battery Module Stacking and Pressing Machine

Kindly reminder: Picture just as reference, please in kind prevail.

Figure 2. Prismatic Cell Battery Stacking Pressing Machine

Kindly reminder: Picture just as reference, please in kind prevail.