The battery electrolyte filling and sealing machine is suitable for vacuum electrolyte filling, vacuum electrolyte diffusion and vacuum pre-sealing processes of pouch cells.

Model:

WA-EF-T260TElectrolyte filling method:

Electrolyte injection in vacuumElectrolyte filling weight:

≤140g (Customizable)Vacuum holding time:

1~99s (Customizable)Sealing stamp width:

2~4mm (Customizable)Sealing temperature:

Max. temperature: 250℃ (Customizable)Product Detail

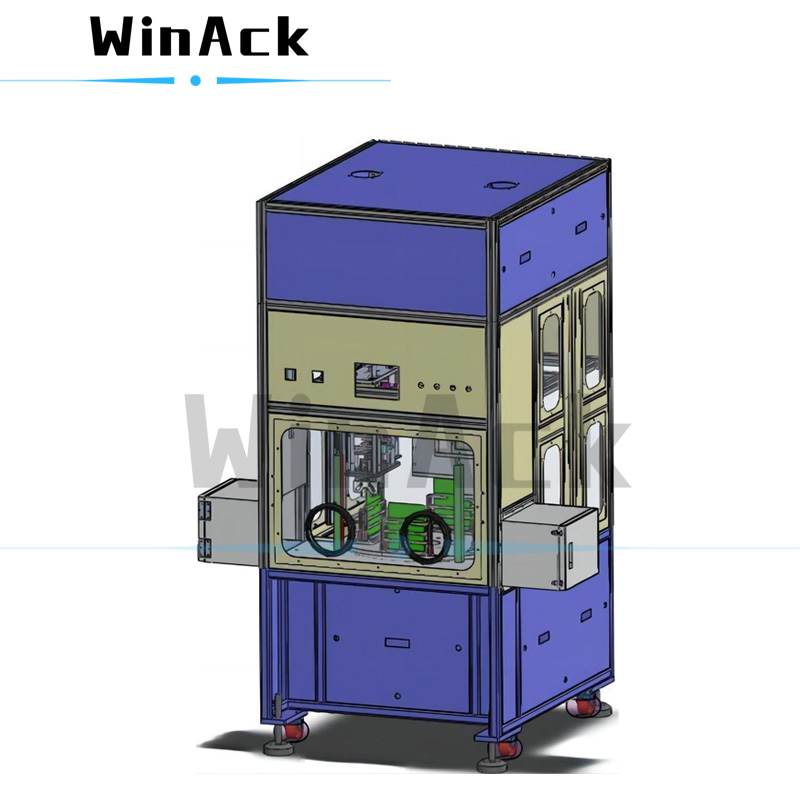

Battery Electrolyte Filling and Sealing Machine for Pouch Cells

Product overview:

The battery electrolyte filling and sealing machine is equipped with a four-station turntable platform, which can be applied to electrolyte filling process of pouch cells. The electrolyte filling machine integrates three processes of vacuum electrolyte filling, vacuum electrolyte diffusion and vacuum pre-sealing in one machine with high efficiency and precision.

The electrolyte filling machine can be used in a drying room, or it can be used with low dew point drying gas or nitrogen gas in the working chamber of the electrolyte filling equipment to ensure the filling environment and battery quality.

Scope of application:

The battery electrolyte filling and sealing machine is suitable for electrolyte filling, electrolyte diffusion and aluminum laminate film pre-sealing of pouch cell, and all three processes are carried out under vacuum.

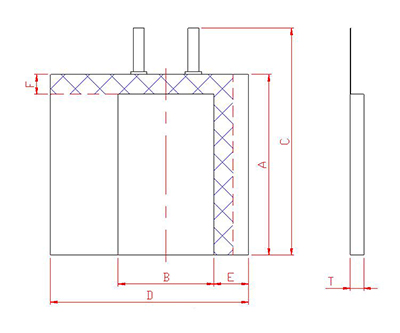

Kindly reminder: The following pouch cell dimensions are for reference only and can be customized according to actual size and requirements.

Table 1. Dimensions of incoming pouch cells

|

NO. |

Items |

Dimension |

Accuracy |

|

A |

Main body length |

150~240mm (Customizable) |

±0.2mm |

|

B |

Main body width |

100~170mm (Customizable) |

- |

|

C |

Total length |

130~280mm (Customizable) |

- |

|

D |

Total width |

190~270mm (Customizable) |

- |

|

E |

Remaining edge |

5~15mm (Customizable) |

±1.0mm |

|

T |

Thickness |

3.0~12.0mm (Customizable) |

±0.3mm |

Brief working steps of the electrolyte filling machine:

1. Manually place the pouch cell into the fixture at the cell loading station of the electrolyte filling machine.

2. The pouch cell is automatically rotated on the turntable and then arrive at the electrolyte filling station, which automatically completes the vacuuming and filling of electrolyte.

3. The pouch cell reaches the vacuum holding station after the turntable rotates automatically and the electrolyte is fully diffused.

4. The pouch cell reaches the pre-sealing station after the turntable rotates automatically and the vacuum heat sealing is completed automatically.

5. The pouch cell reaches the cell loading station after the turntable rotates automatically, where the pouch cell is unloaded manually.

Features:

1) Four-station turntable platform with manual loading at the first station and automatic completion of vacuum electrolyte filling, vacuum electrolyte diffusion and vacuum pre-sealing processes at the subsequent three stations.

2) The electrolyte filling machine is equipped with a precision electric plunger pump to ensure the accuracy of electrolyte filling.

3) The electrolyte filler is equipped with a vacuum holding station that can be set for vacuum level and holding time to ensure adequate diffusion of the electrolyte.

4) The pouch cell vacuum pre-sealing station is equipped with a hard seal head made of H62 brass, which provides good temperature uniformity and sealing consistency.

5) The dustproof outer cover of the electrolyte filling machine has a good sealing effect, and the interface for filling protective gas and exhaust is reserved.

6) In order to avoid the incident of work injury caused by the rotation of the loading turntable during manual loading by mistake, the manual loading station is equipped with double protection of safety grating protection and battery loading confirmation protection.

7) The electrolyte filling machine is equipped with a vacuum source interface, which can be equipped with an optional vacuum pump or connected to the user's own vacuum source.

Technical specifications

|

Product name |

Battery Electrolyte Filling Machine |

|

Product model |

WA-EF-T260T |

|

Electrolyte filling method |

Electrolyte injection in vacuum |

|

Electrolyte filling weight |

≤140g (Customizable) |

|

Operation efficiency |

1~2PPM Kindly reminder: Based on the maximum electrolyte injection time of 20 seconds, maximum holding time of 20 seconds, maximum pre-sealing station running time of 16 seconds. |

|

Filling accuracy |

±0.8g (At≤140g) |

|

Accuracy of electrolyte injection pump |

±0.1g |

|

Utilization rate |

≥95% |

|

Yield rate |

≥99% |

|

Control method |

Touch Panel & PLC |

|

AC input power |

Single-phase 220VAC±10% / 50Hz (Customizable) |

|

Power: 4kW |

|

|

Input compressed air supply |

≥0.7MPa |

|

Vacuum source |

≤-0.095MPa, 20L/min. Kindly reminder: The vacuum pump is optional. |

|

Nitrogen source |

≥0.02kPa (Select on demand) |

|

Optional functions |

Barcode scanning and weighing |

|

Size(L*W*H) |

2300*1500*2400mm |

|

Weight |

About 1450kg |

|

Specifications of vacuum electrolyte diffusion |

|

|

Holding method |

One-time vacuum holding |

|

Maximum vacuum degree |

-0.09MPa |

|

Holding time |

1~99s Kindly reminder: The holding time will directly affect the efficiency of the electrolyte filling machine. |

|

Specifications of the vacuum pre-sealing machine |

|

|

Sealing stamp width |

2~4mm (Customizable) Accuracy: ±0.1mm |

|

Sealing head length |

260mm (Customizable) Accuracy: ±0.2mm |

|

Sealing head pressure |

0.3~ 0.6MPa |

|

Sealing time |

0.5~99s |

|

Sealing temperature |

Max. temperature: 250℃ (Customizable) Accuracy: ±3℃ |

|

Sealing head material |

Brass & NAK80 |

|

Sealing effect |

Aluminum laminate film does not detach from each other, good sealing, flat surface, no wrinkles, no bubbles. |