The vacuum standing box is specially designed for battery electrolyte diffusion and degassing, which allows electrolyte to thoroughly saturate the electrodes, can be used inside the glovebox.

Model:

WA-EDD-500Inner chamber dimensions:

W500*D400*H300mm (Customizable)Vacuum level:

≤-0.095MPaNumber of cycles:

1~5Vacuuming time:

1~60minVacuum standing time:

1~60minProduct Detail

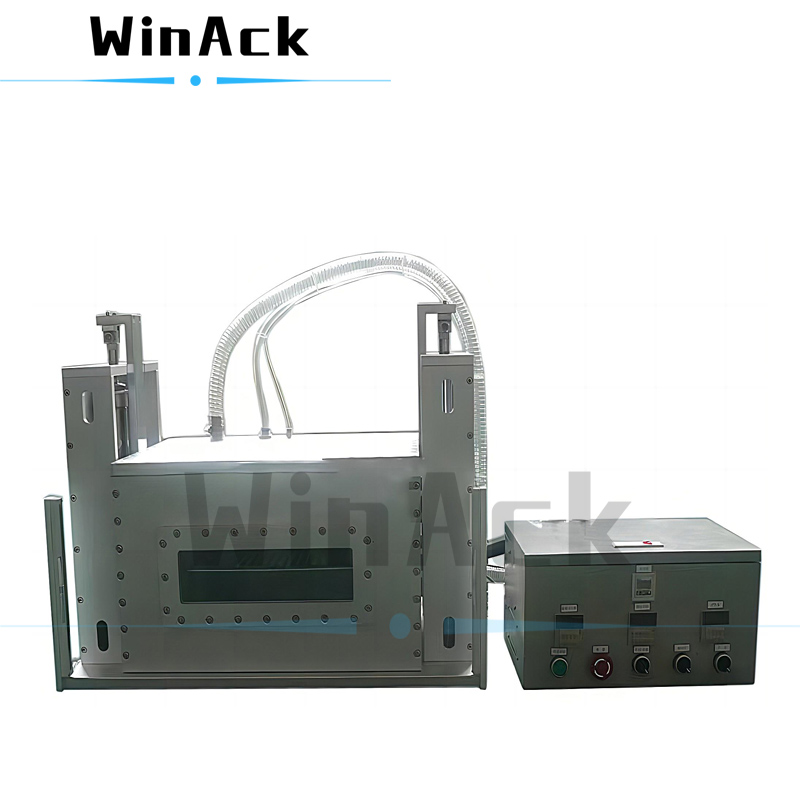

Electrolyte Diffusion and Degassing Chamber

Product overview:

The vacuum standing box is a professional electrolyte diffusion and degassing chamber for lithium-ion batteries, where the vacuuming time and vacuum holding time can be set and multiple cycles can be performed. The brief operation procedure is as follows.

Manually place the battery cells into the vacuum standing box, after starting, the double cylinders to close the vacuum chamber. At this time, the electrolyte diffusion machine automatically connects to the vacuum source to pump vacuum and reach the set vacuum degree to enter the vacuum standing condition. Filling the vacuum standing box with nitrogen gas is optional at this stage, which can further accelerate the diffusion of the electrolyte. After the vacuum holding process, the electrolyte diffusion machine will automatically unload the pressure and the cylinders will act to open the vacuum box.

Scope of application:

The electrolyte diffusion and degassing chamber is used to remove the air from the battery cells after electrolyte injection; after reaching the set vacuum conditions, the battery cells perform vacuum standing to promote the absorption of electrolyte by the electrodes.

In addition, the vacuum standing box can also be applied to vacuum resting and vacuum storage of various materials, which helps diffusion and defoaming, etc.

Features:

1) The vacuuming time, vacuum standing time and number of cycles can be pre-set to meet different requirements.

2) The vacuum level of the vacuum standing box can be maintained stably, and the electrolyte diffusion effect is good, which can realize good absorption of electrolyte by the electrodes.

3) The plexiglass observation window is designed in front of the vacuum standing box, which can be used to observe the product changes inside the chamber.

4) The control unit and the vacuum standing box of the electrolyte diffusion machine are of split design, which allows the vacuum standing chamber to be placed in the glovebox and on the production line for use.

5) The electrolyte diffusion chamber is equipped with a safety protection light curtain to prevent misoperation of the foot switch during operation.

6) Safe and stable operation, reliable control, easy and simple operation.

Technical specifications

|

Product name |

Electrolyte Diffusion and Degassing Chamber |

|

Product model |

WA-EDD-500 |

|

Inner chamber dimensions |

W500*D400*H300mm (Customizable) |

|

Vacuum level |

≤-0.095MPa |

|

Number of cycles |

1~5 |

|

Vacuuming time |

1~60min |

|

Vacuum standing time |

1~60min |

|

Chamber opening stroke |

<300mm (Customizable) |

|

Utilization rate |

≥95% |

|

Yield rate |

≥99% |

|

AC input power |

Single-phase 220VAC±10% / 50Hz (Customizable) |

|

Power: 200W |

|

|

Input compressed air supply |

≥0.7MPa, 5L/min |

|

Vacuum source |

≤-0.098MPa, 300L/min. Kindly reminder: The vacuum pump is optional. |

|

Dimensions |

L750*W500*H780mm |

|

Weight |

About 100kg |